Sliding Head Lathe

Sliding Head Department

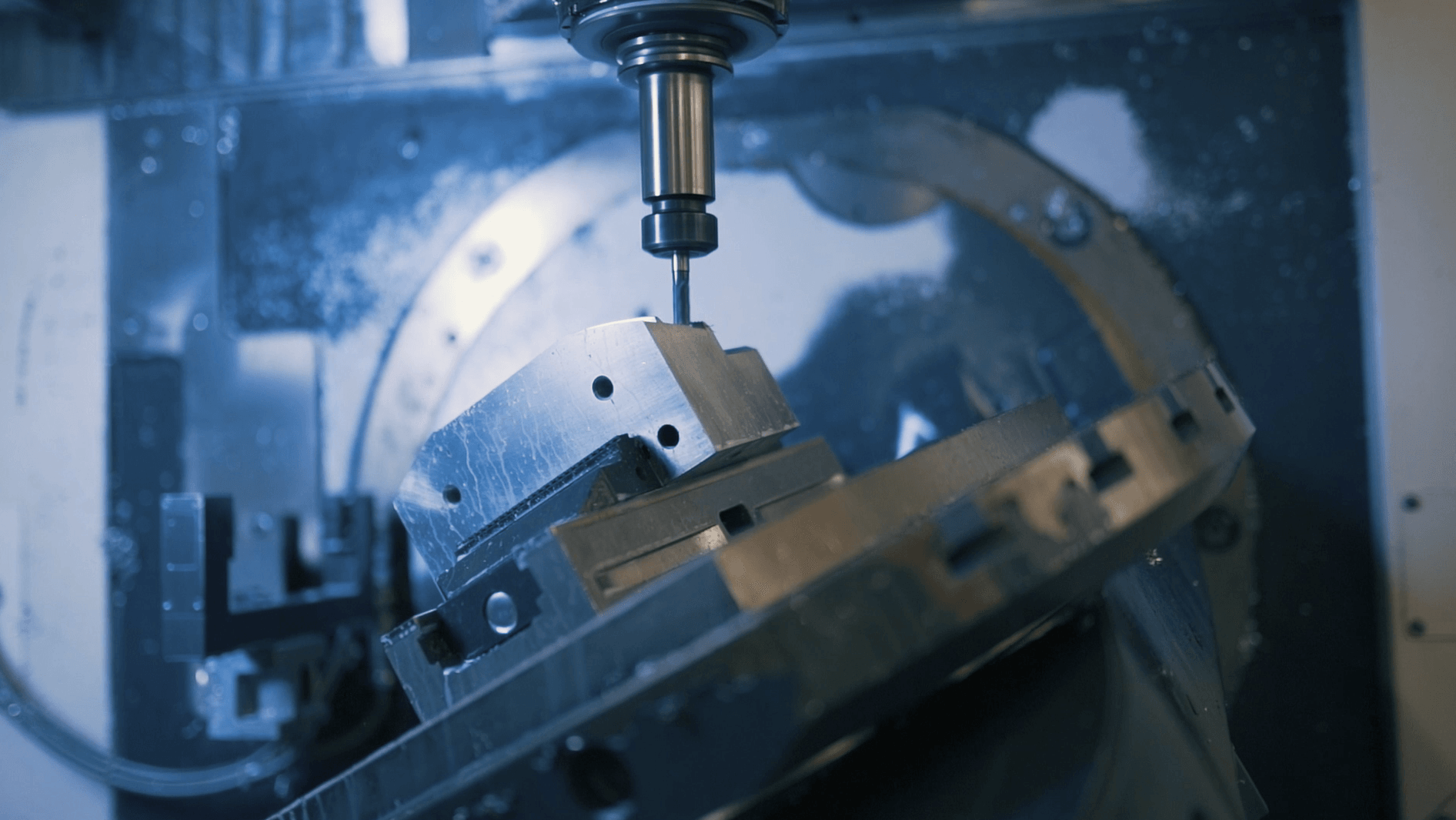

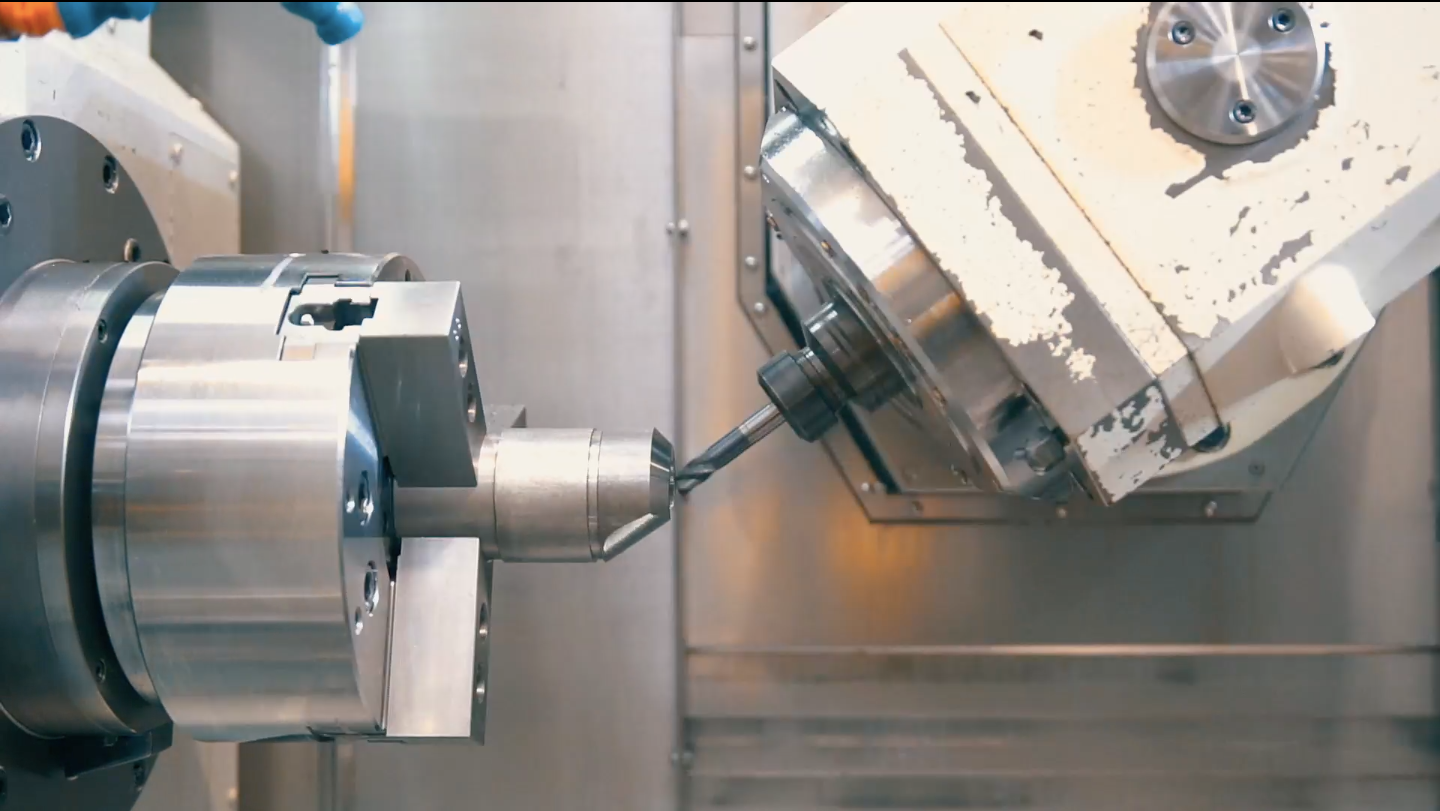

Our Sliding Head Machines are designed to work within a broad range of manufacturing requirements. From high volume and complex parts that need to be manufactured 24 hours a day, to small samples and prototype batches, this service is perfect. The fleet of machines that we use has the capability to manufacture components as small as 1mm in diameter up to 50mm. The sliding head machine has the high power, performance, and accuracy for simple parts up to complex aerospace components.

Contact Us

Get in touch here

We will get back to you as soon as possible.

Please try again later.

Expertise

High volume small turned parts

Low Volume Prototype Batches

Die Making Consumables

Bolts and Fasteners

Heatsinks

Gear Cutting / Hobbing

Shafts & Pins

Aerospace Components

Our Sliding Head Machines

Rotec has 17 fully automated sliding head machines that operate around the clock to meet our customers demands.

In 2021, Rotec invested in a further 4 Star machines, and more are coming soon in 2022…

STAR SA-12

7 axis machine, 16 mm maximum diameter, Sub-spindle, Live tooling, Magazine bar feed. Can run 24 hrs unmanned

Material We Work With

- Aluminium

- Stainless Steel

- Titanium

- Mild / Carbon Steel

- Brass / Copper

- Nickel Super Alloys

- Many more…

If you have a specific material that you would like us to work with, please Contact Us

Sliding Head Services – The Benefits

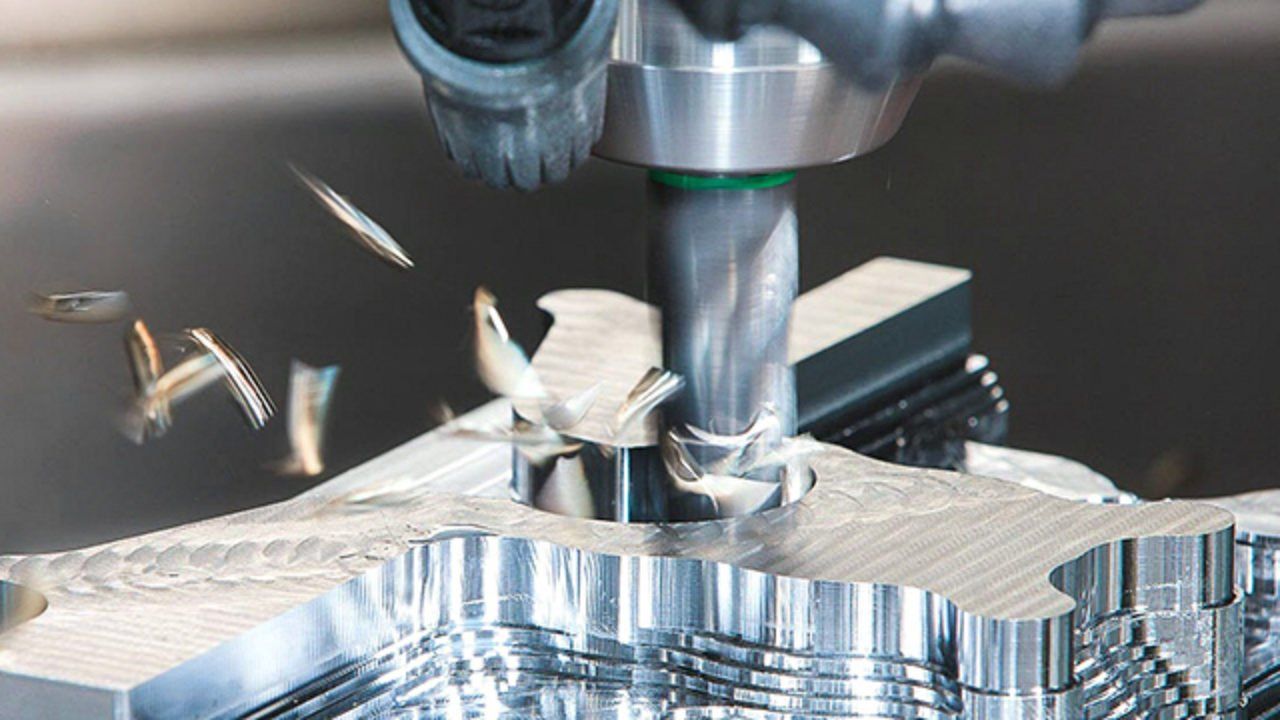

- High quality - consistency of performance and standards is important when manufacturing complex components. The sliding head services turn the most complex parts and those small, delicate components with precision and to exact specifications. This remains consistent from small right through to large production runs.

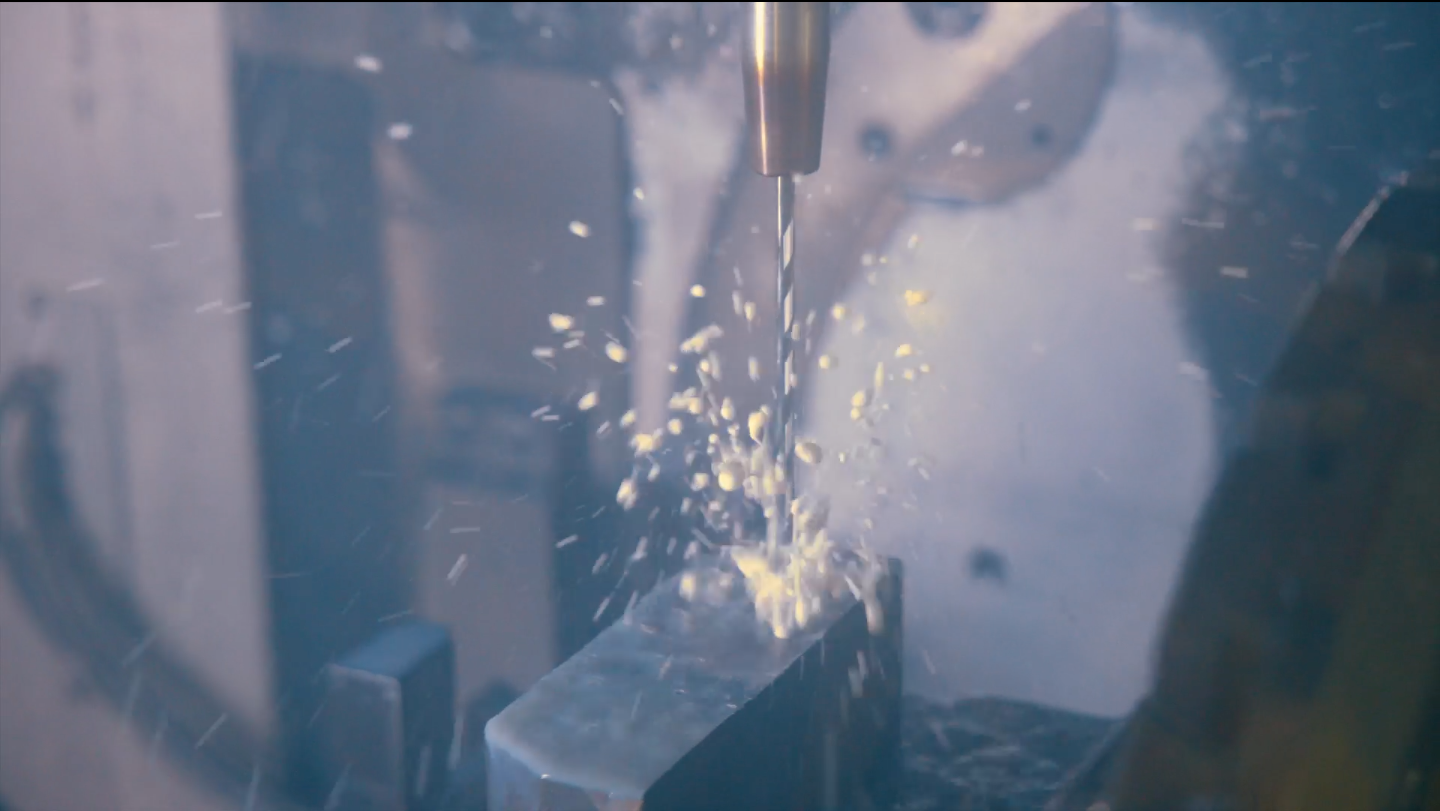

- Multi-process – CNC machining tasks can be complex and broad in requirements. A sliding head lathe has the capability for turning, drilling, milling, grooving, boring, screw-cutting, cross drilling, to meet specific needs.

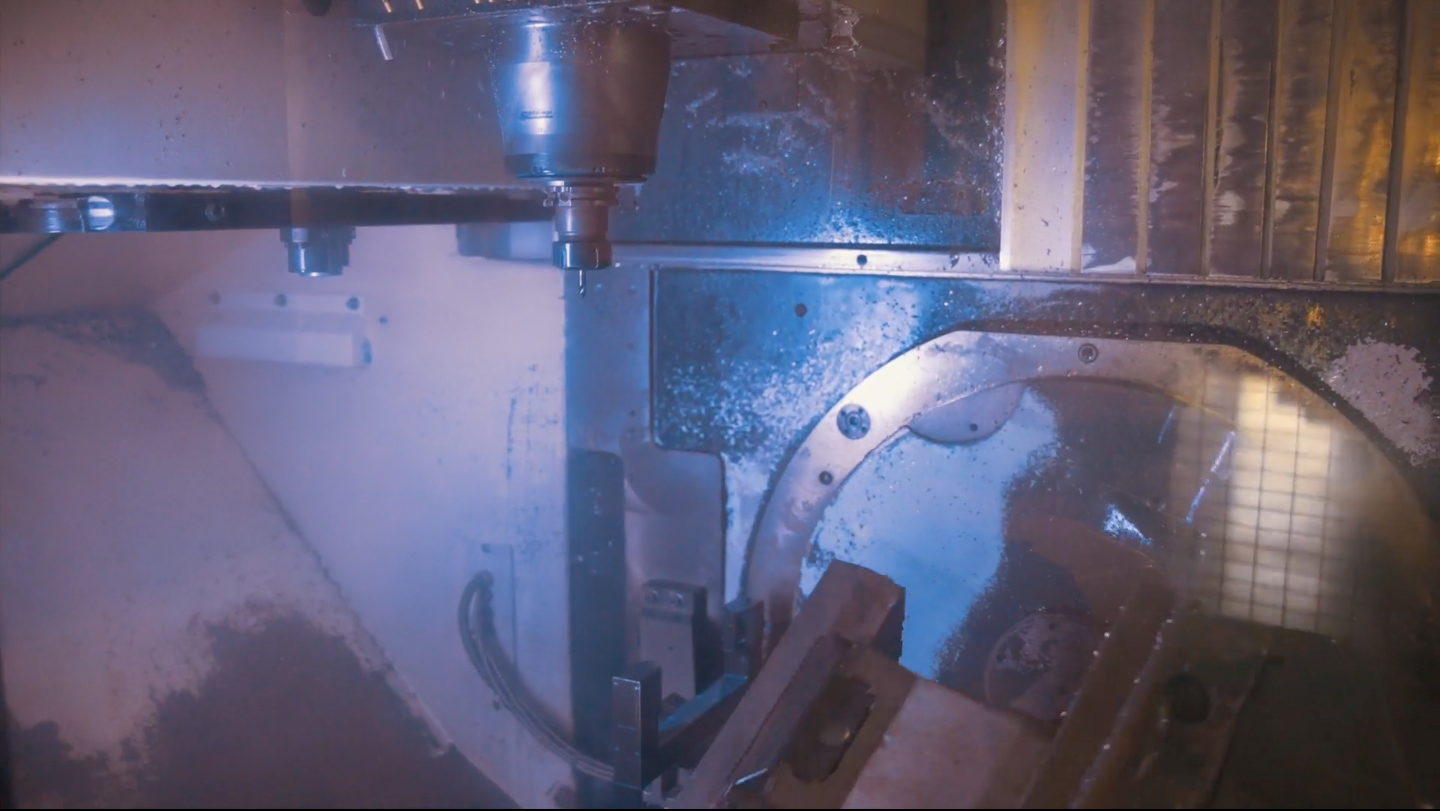

- 24-hour capability – some production runs require constant movement, 24 hours a day. Our specialist Star sliding machines are designed to deliver just that, without diminishing quality of performance. They can remain unmanned for long periods, and the CNC sliding head lathes are equipped with non-stop processing capabilities to make those long runs possible.

- Reduced costs – with precision and long-run capabilities, the CNC sliding head machines offer greater reduction in overall production costs.

- Meet deadlines with faster times – with a rear spindle alongside a main spindle, the sliding head machines enable secondary processes, effectively halving the potential timescale for production when compared with a traditional fixed head machine.

Customer Focused

We make sure our customers are incredibly satisfied with every order, we hold a large repeat customer base and some of our clients have been with us since the beginning.

Expert Team

Your project will be handled by professionals who care. We make sure you have a dedicated team working for you.

Quality Assurance

Get the support you need to ensure that things runs smoothly. We’re here seven days a week to answer any question.

24hr Automated Facility

We have an automated 24 hour facility and professional team to support you at all times from Mon-Fri: 7:30am - 5pm

Our Services

Our use of sliding head lathes ensures that cycle times and costs are significantly reduced. Achieving up to 39 machining positions with 8 axes, often a component can be completed in one single set-up, improving efficiencies.

Our CNC machining services allow for the creation of complex milled parts at velocity. This expands the potential range of materials without minimising efficiency and standards. We can manufacture complex parts in a wide range of sizes, quantities, and with multiple angled features.

Our team continues to refresh our fleet of machines, investing significantly in our Turning and Mill/Turn technology. This allows us to remain ahead of the game, providing a tailored service and solution to our customers that is hard to match within the industry.

The 3 axis CNC machining services offer the best value in the industry for small CNC machines. It packs a punch, an efficient smaller package that delivers big results and high standards of productivity. The best way to maintain productivity in a smaller space.

4 axis CNC machining is where the 4th axis rotates whilst the machine is not cutting, aiding precision. Our range of CNC machining services is designed to offer a wide range of precision to fit any manufacturing complexities and demand.

We continue to innovate, refining our 5 axis CNC machining services for maximum output at reduced time and cost. The 5 axis provides you with the power and precision for myriad uses, maintaining accuracy and delivering consistently.

Utilising the very latest technology in CAD/CAM helps us to provide compliance and consistent manufacturing processes for our clients. It helps us to deliver CNC machining services that are precise, complete the process right the first time and reduce lead times.

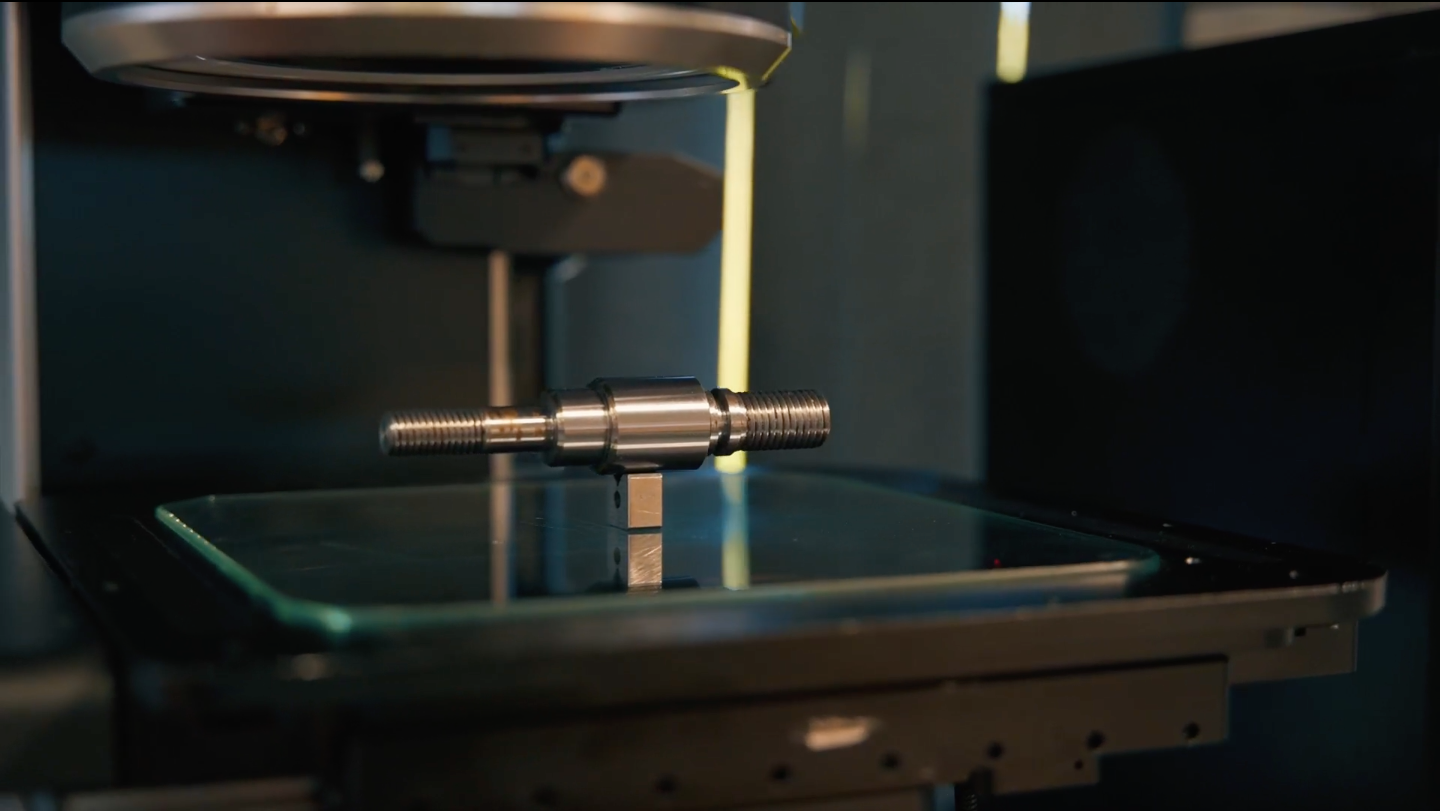

CMM inspection is another service Rotec offers to boost the accuracy and consistency of manufacturing processes. It involved precision CMM inspection services that takes CAD models and 2D drawing formats and provides a detailed report tailored to each client and process.

Creating a prototype is an important part of the manufacturing process. Our services allow our clients to see a product, part, or concept in action before making a decision on whether to continue production or make necessary changes.

Our Sliding Head Company

Rotec holds a firm belief in the future of British Engineering. As a precision machining company we are committed to remaining at the forefront of manufacturing technology and to invest in continued research & development, ensuring we maintain our competitive edge amongst global competition.

Rotec is proud of its diverse customer base with no single industry dominating the production within Rotec. From underground to space, Rotec supports a myriad of sectors.

Contact Us

If you're a potential client and have a project we can discuss, our journey together begins here. Fill out the form and we'll be in touch or use the contact details below

Contact Us

We will get back to you as soon as possible.

Please try again later.

Rotec Engineering Group, Enterprise Way, Vale Business Park, Evesham WR11 1GS United Kingdom

Phone: 01386 424111

Email: Info@rotec-ltd.com

Office Hours :

Mon-Fri : 7:30am - 5pm