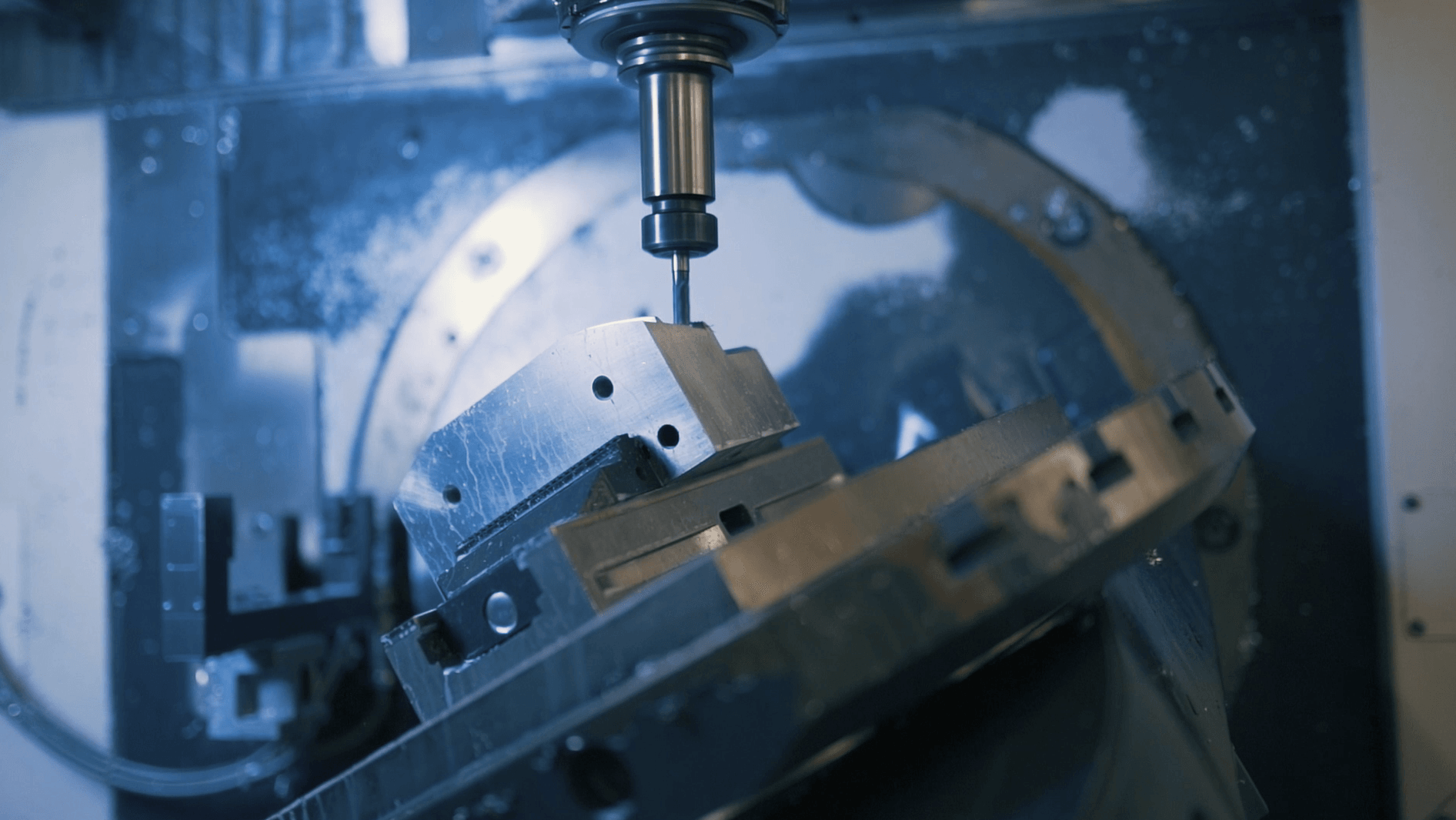

5 Axis CNC Machining

5 Axis CNC Machining Department

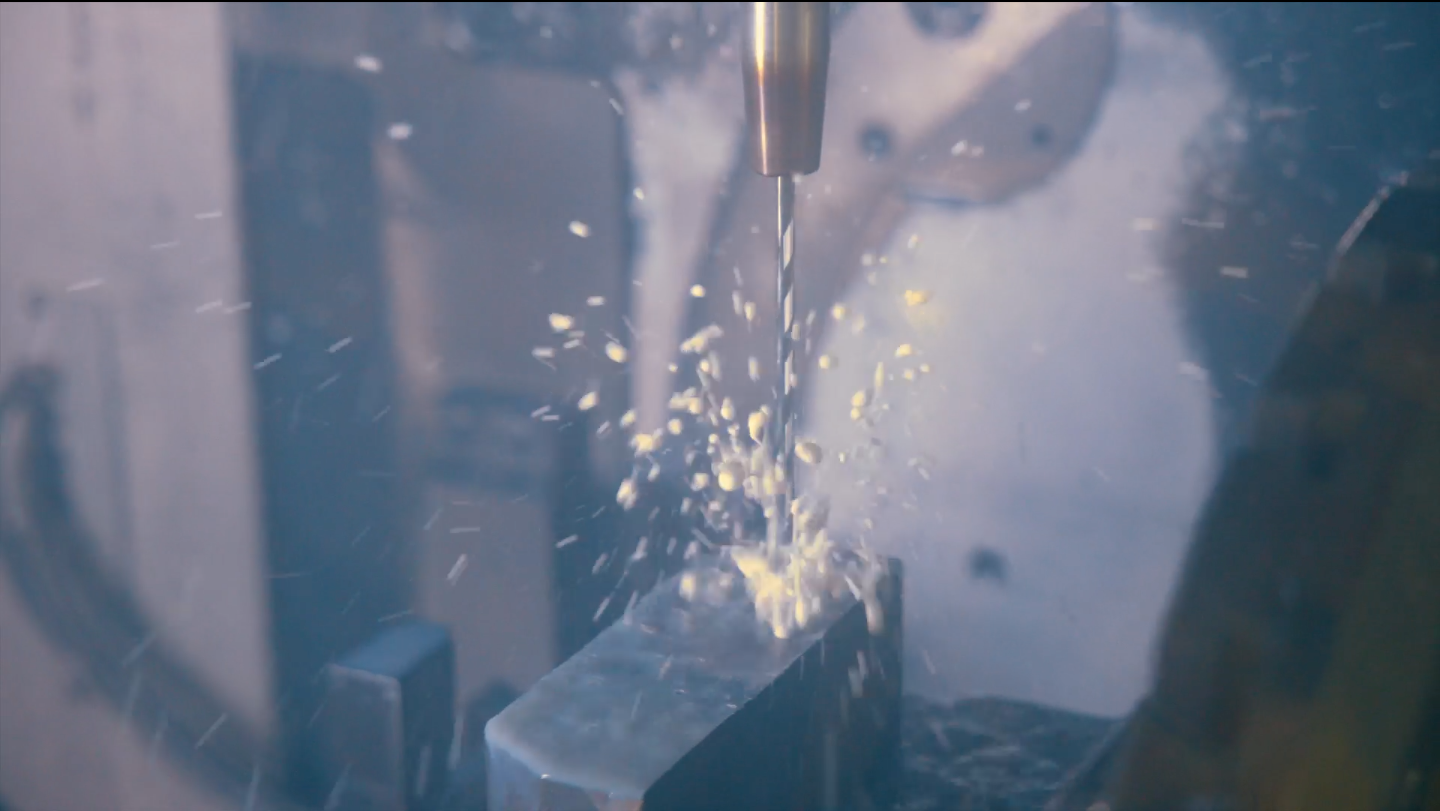

The 5 Axis CNC Machining service from Rotec uses the latest technology and techniques to ensure that our customers have access to precision engineering solutions that match their expectations completely. The 5 Axis provides the stable and accurate process through which complex challenges and technical specifications can be met and exceeded, increasing output, lowering costs, and maintaining precision and consistency. The

5 Axis CNC machining service allows for flexibility, cutting at all angles in an efficient way that drastically cuts production time.

Contact Us

Get in touch here

We will get back to you as soon as possible.

Please try again later.

Expertise

High volume small turned parts

Low Volume Prototype Batches

Die Making Consumables

Bolts and Fasteners

Heatsinks

Gear Cutting / Hobbing

Shafts & Pins

Aerospace Components

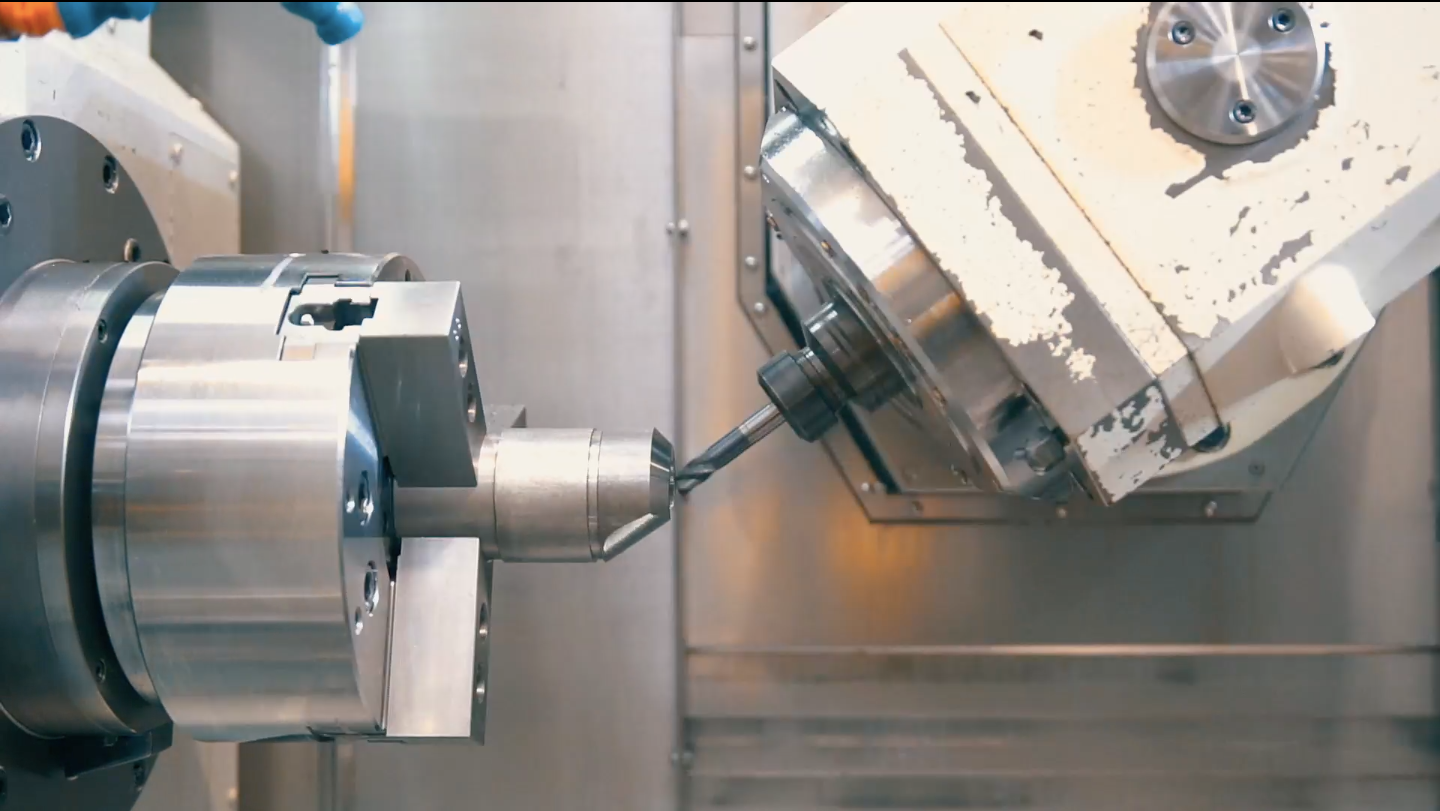

Our 5 Axis CNC Machines

Accuracy and consistency are everything to our customers. Our 5 Axis CNC Machining services aim to provide maximum output with lower costs, power, precision, and less time involved.

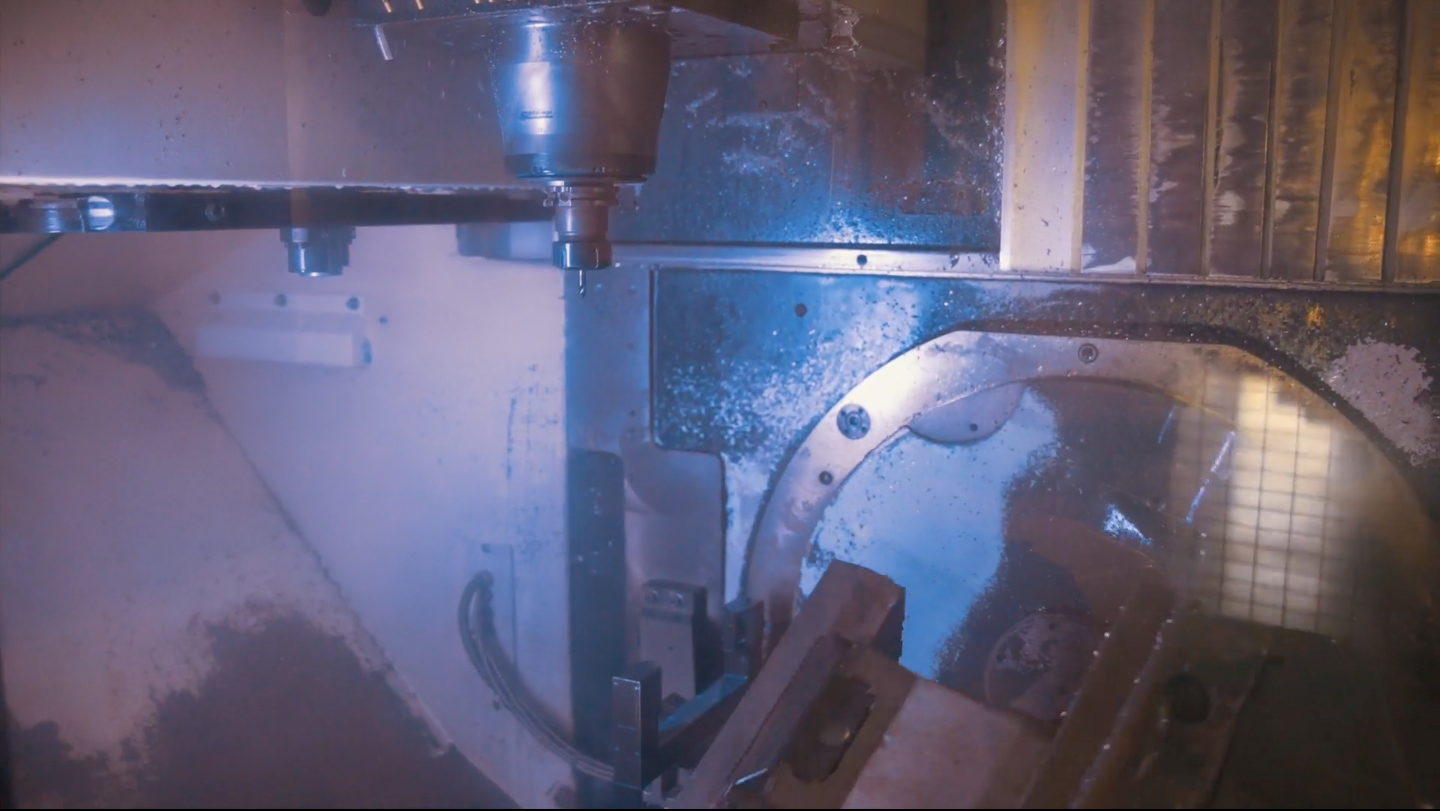

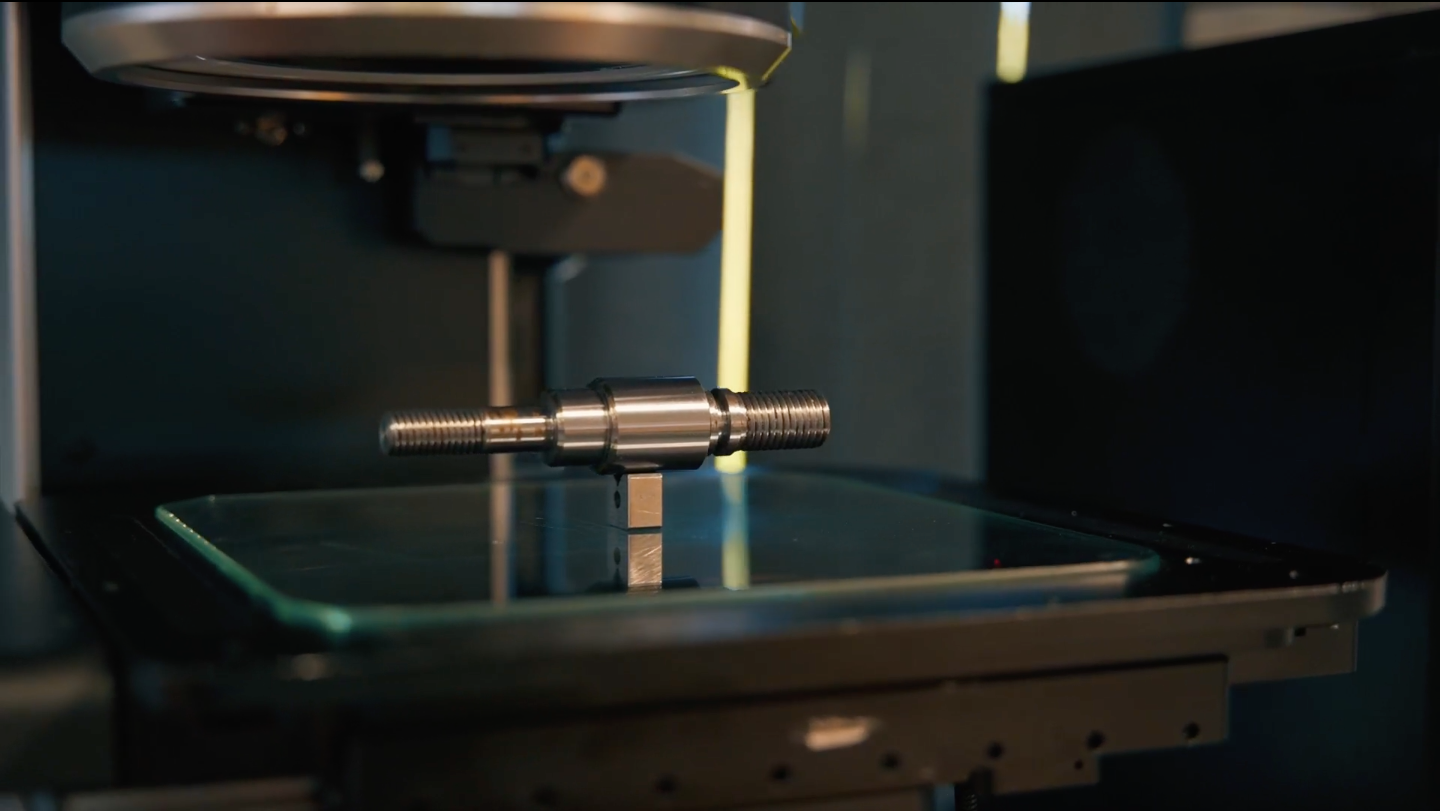

DMG MORI DMU 50U

This is one of our latest machines with 5 axis simultaneous machining, swivel rotary table 12,000 rmp spindle and a 24 position tool changer, and probe inspection

STAR SA-12

7 axis machine, 16 mm maximum diameter, Sub-spindle, Live tooling, Magazine bar feed. Can run 24 hrs unmanned

Material We Work With

- Aluminium

- Stainless Steel

- Titanium

- Mild / Carbon Steel

- Brass / Copper

- Nickel Super Alloys

- Many more…

If you have a specific material that you would like us to work with, please Contact Us

Benefits of CNC Sliding Head Machining

By investing in our 5 Axis CNC machining services our customers experience a range of benefits, improving manufacturing output in a measurable way.

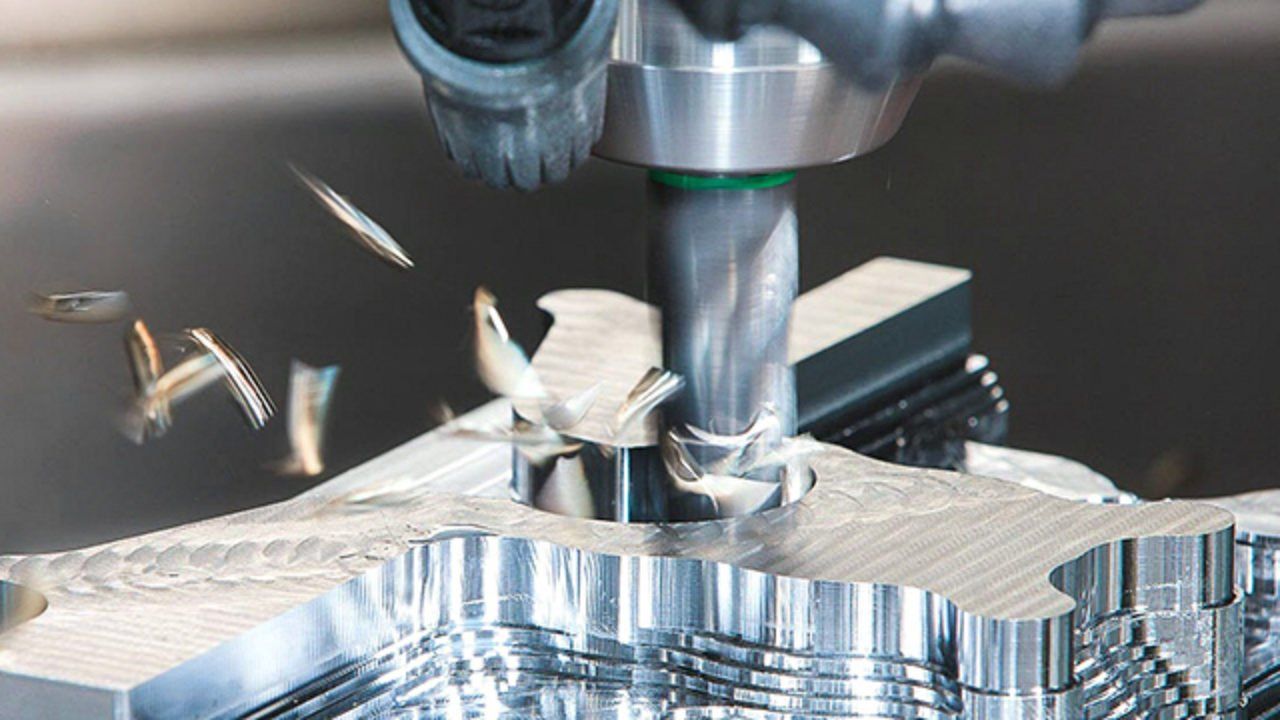

- Increased accuracy and precision – a 5 axis CNC machine operates with greater precision than traditional 3 axis CNC machinery. It allows for a higher level of complexity in potential parts and components.

- Lower lead times – production speed is important with any project and the arrangement of the cutting tools on a 5 axis CNC machine means that cycle times are much faster, with a greater potential output.

- Simple setup – a 5 axis machine allows for all pieces you have to be set up at one time, even for complex geometries. This means faster production, with minimised errors and operational costs.

- Complexity increased – one of the major benefits over a 3 axis machine is that you no longer have to remove workpieces during manufacturing. Instead, complicated angles and geometries can be processes with high efficacy and accuracy.

- Improved finish

– the material is much closer on a 5 axis machine, meaning a better finish on the surface, even with the most complex of parts. Tighter angles can be reached with the improved drilling process present within this setup.

Customer Focused

We make sure our customers are incredibly satisfied with every order, we hold a large repeat customer base and some of our clients have been with us since the beginning.

Expert Team

Your project will be handled by professionals who care. We make sure you have a dedicated team working for you.

Quality Assurance

Get the support you need to ensure that things runs smoothly. We’re here seven days a week to answer any question.

24hr Automated Facility

We have an automated 24 hour facility and professional team to support you at all times from Mon-Fri: 7:30am - 5pm

Our Services

Our use of sliding head lathes ensures that cycle times and costs are significantly reduced. Achieving up to 39 machining positions with 8 axes, often a component can be completed in one single set-up, improving efficiencies.

Our CNC machining services allow for the creation of complex milled parts at velocity. This expands the potential range of materials without minimising efficiency and standards. We can manufacture complex parts in a wide range of sizes, quantities, and with multiple angled features.

Our team continues to refresh our fleet of machines, investing significantly in our Turning and Mill/Turn technology. This allows us to remain ahead of the game, providing a tailored service and solution to our customers that is hard to match within the industry.

The 3 axis CNC machining services offer the best value in the industry for small CNC machines. It packs a punch, an efficient smaller package that delivers big results and high standards of productivity. The best way to maintain productivity in a smaller space.

4 axis CNC machining is where the 4th axis rotates whilst the machine is not cutting, aiding precision. Our range of CNC machining services is designed to offer a wide range of precision to fit any manufacturing complexities and demand.

We continue to innovate, refining our 5 axis CNC machining services for maximum output at reduced time and cost. The 5 axis provides you with the power and precision for myriad uses, maintaining accuracy and delivering consistently.

Utilising the very latest technology in CAD/CAM helps us to provide compliance and consistent manufacturing processes for our clients. It helps us to deliver CNC machining services that are precise, complete the process right the first time and reduce lead times.

CMM inspection is another service Rotec offers to boost the accuracy and consistency of manufacturing processes. It involved precision CMM inspection services that takes CAD models and 2D drawing formats and provides a detailed report tailored to each client and process.

Creating a prototype is an important part of the manufacturing process. Our services allow our clients to see a product, part, or concept in action before making a decision on whether to continue production or make necessary changes.

Our 5 Axis CNC Machining Company

Our 5 Axis CNC Machining Services make up part of our wider precision engineering service offerings. We work with customers within the energy, medical, automotive, and aerospace industries, to name just a few. The Rotec team continues to invest in the latest technologies, looking to boost efficiencies, manufacturing capabilities and output, increase productivity and accuracy of machining, whilst lowering costs and production lead times for our customers with often strict requirements.

Contact Us

If you're a potential client and have a project we can discuss, our journey together begins here. Fill out the form and we'll be in touch or use the contact details below

Contact Us

We will get back to you as soon as possible.

Please try again later.

Rotec Engineering Group, Enterprise Way, Vale Business Park, Evesham WR11 1GS United Kingdom

Phone: 01386 424111

Email: Info@rotec-ltd.com

Office Hours :

Mon-Fri : 7:30am - 5pm