~ How CNC Machining is Used in Aerospace ~

What is aerospace CNC machining?

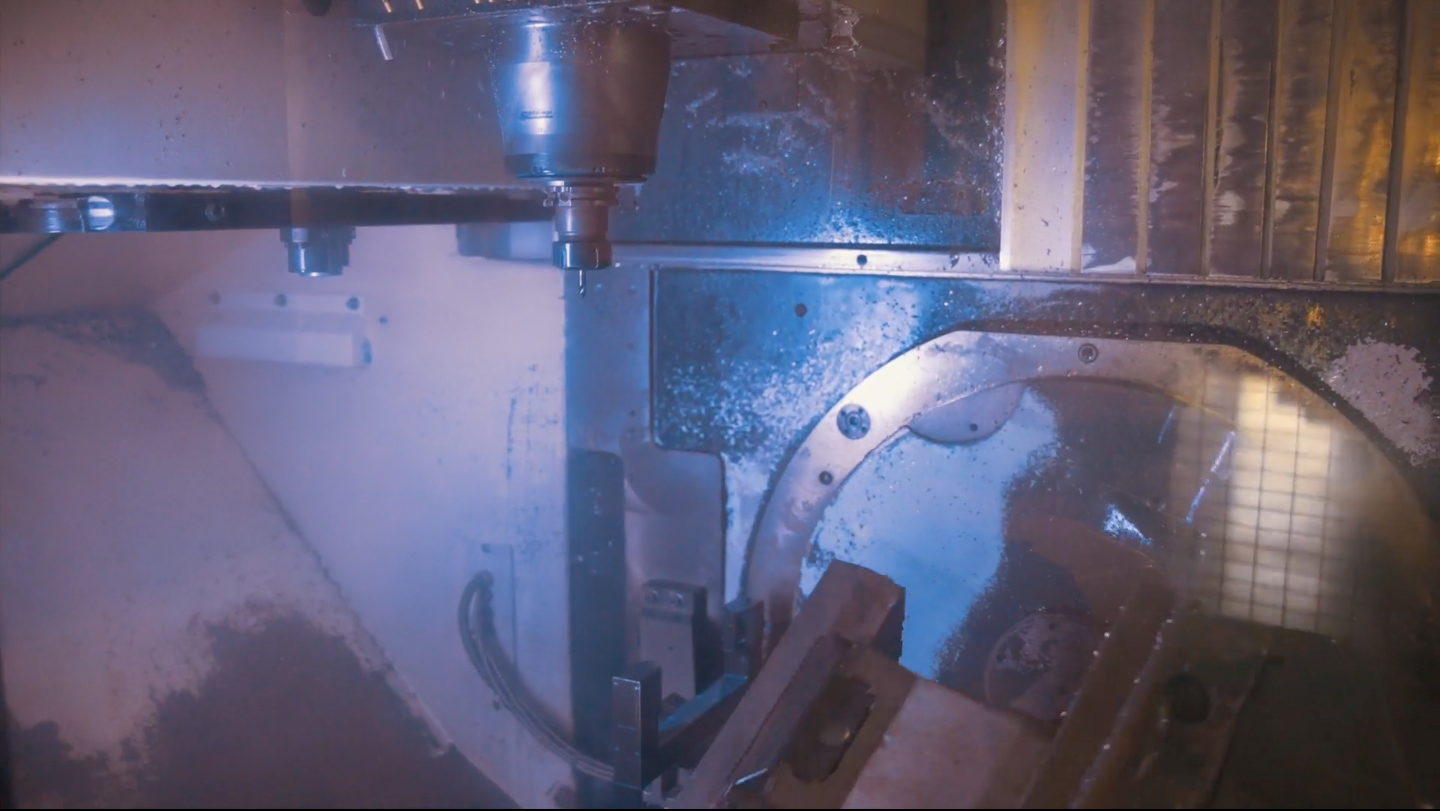

The aerospace industry requires CNC machined components to be manufactured to some of the highest quality standards, one of them being the AS9100 specification.Once a component has been designed and tested to ensure it meets all requirements, it then needs a manufacturing method that can hold them. This is where precision CNC machining is essential.

Aerospace CNC machining creates parts that are used in the assembly process for aircraft, space shuttles, and other aerospace applications. There are many different types of aircraft parts for instance, including hinges, clamps, and a wide range of custom parts, all ranging in size and scope and used in the production of seats, oxygen generation systems, filters, and more.

What are the different applications for CNC machining in aerospace?

When you first think of what makes up an aircraft, you will automatically think of the engine or the wings of the plane. To put things into perspective and to realise how important it is to be precise with every single component produced, a Boeing 747 is made up of over 6 million components.

CNC machining is used within various applications in the aerospace industry. This includes creating components and parts for:

- Seats in aircraft and spacecraft

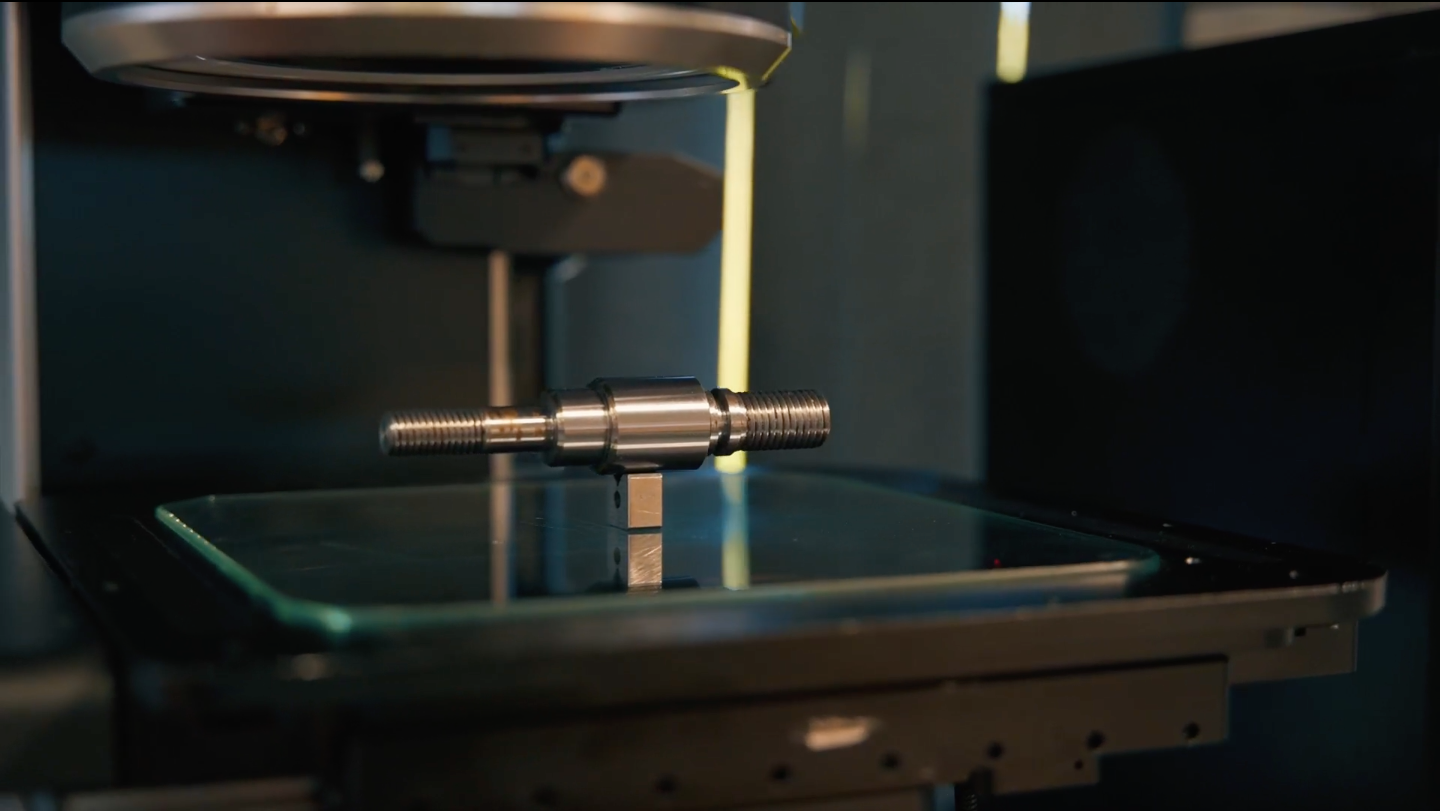

- Shafts for transferring power in applications

- Oxygen generation components

- Valve components

- Electrical connectors

- Strong missile housings

- Complicated air and liquid filter bodies

There is a slightly different focus in how CNC machining is used within aircrafts and spacecraft:

CNC in aviation

Every part of the production for an aircraft must follow stringent processes. Whether this is a cargo plane, a passenger airline, or a fighter jet, accuracy is vital in all component manufacturing. The engine of any aircraft must keep the plane in the air for as long as required, processing and using fuel efficiently. Away from the engine, the cockpit is vital, with smaller parts and interconnected components providing crucial function throughout a flight. Every single part comes together to provide aircraft that functions to a high and consistent level and passes robust safety regulations.

CNC in spacecraft

There are so many minute and important components that make up the overall design of a rocket and spacecraft. The entire concept of a spacecraft being built to withstand the pressures of travelling in space is a mind-blowing one. The craft and precision that goes into this manufacturing process requires the high standards that CNC machining delivers to become the safest and most effective way to ensure safety and robustness.

What materials are used in aerospace CNC machining?

The materials used within CNC machining for aerospace must be lightweight yet durable. There are materials such as aluminium that provide robustness yet lightweight nature, but the different types of materials can be broken down into these two simple areas:

Lightweight materials

The strength and weight of components for aerospace production is a vital part of the process. This is why steel may be seen as a strong metal, but it is certainly not lightweight. The use of steel would mean a heavier and less fuel-efficient aircraft. Aluminium alloys and titanium are therefore preferred due to the strength and lightweight nature of both, and they are ideal for both external and internal aircraft components.

High performance plastics

CNC machining for aerospace includes the creation of strong and complex plastic parts that are lightweight. It offers the high-precision required for such applications, producing parts that are used for internal wall panels, aircraft doors, conduits for wiring, ventilation ducts, bearings and other parts of an aircraft.

With both metal and plastics, using the very best materials and combining that with precision CNC machining provides the stable foundations from which to build any aircraft or spacecraft. This is vital within the aerospace industry and CNC machining processes are difficult to match.

Benefits of CNC machining in aerospace

CNC machining brings many benefits to the aerospace industry, including:

High standard of performance

There are stringent requirements for aerospace parts to ensure safeguarding against failure. CNC machining provides high and consistent performance in materials that are difficult to machine.

Light weight in nature

For any equipment that is involved in aerospace, there is a desire for it to be as light as possible. CNC machining offers the capability to produce components and structures from lightweight materials that are robust and strong.

Precision

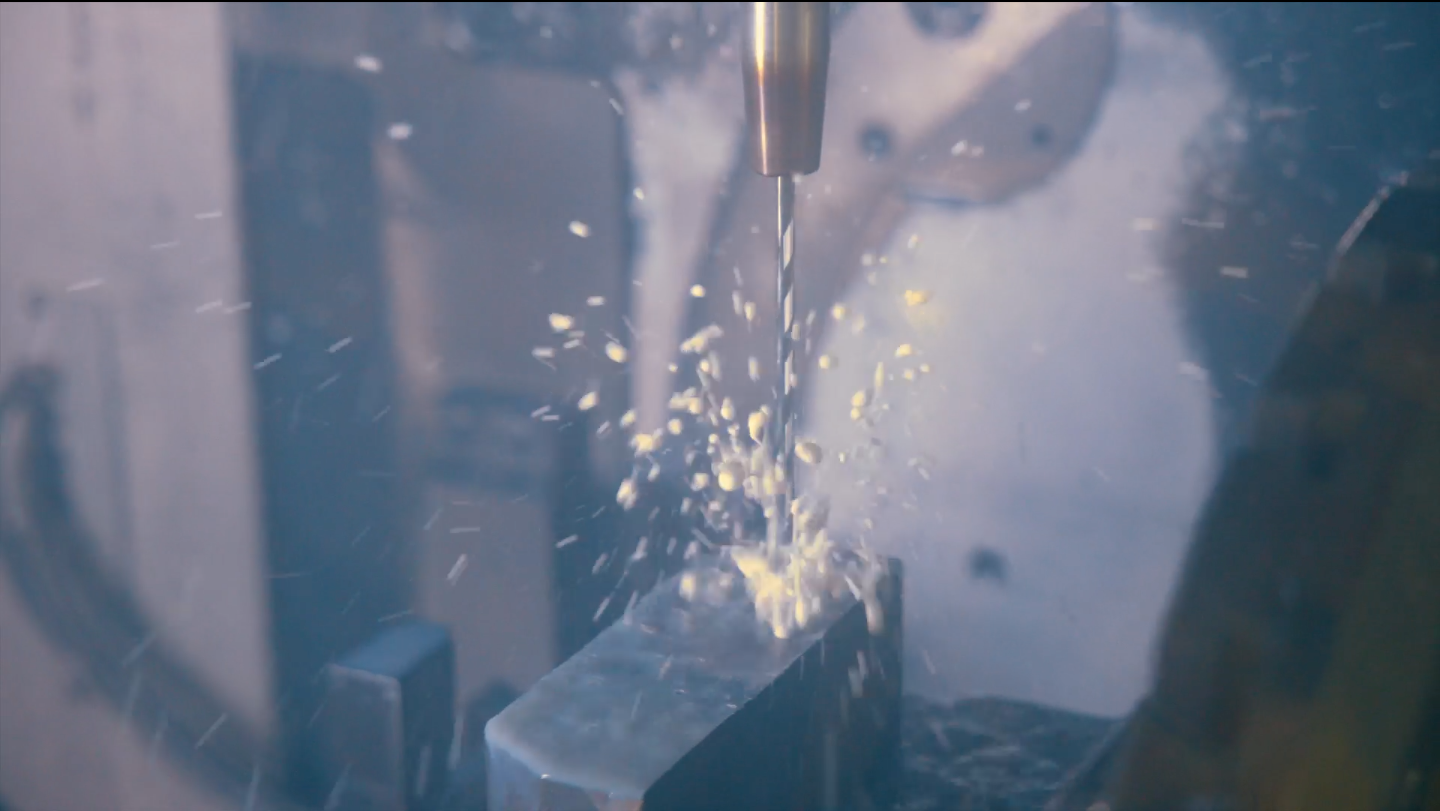

Precision and accuracy are key within the aerospace industry. CNC machining offers a precise process to reduce the risk of manufacturing defects and increased tight tolerances. This high accuracy, precision engineering leaves no room for human error. This is vital in this industry, where an aircraft is in flight for long periods and in service for many years.

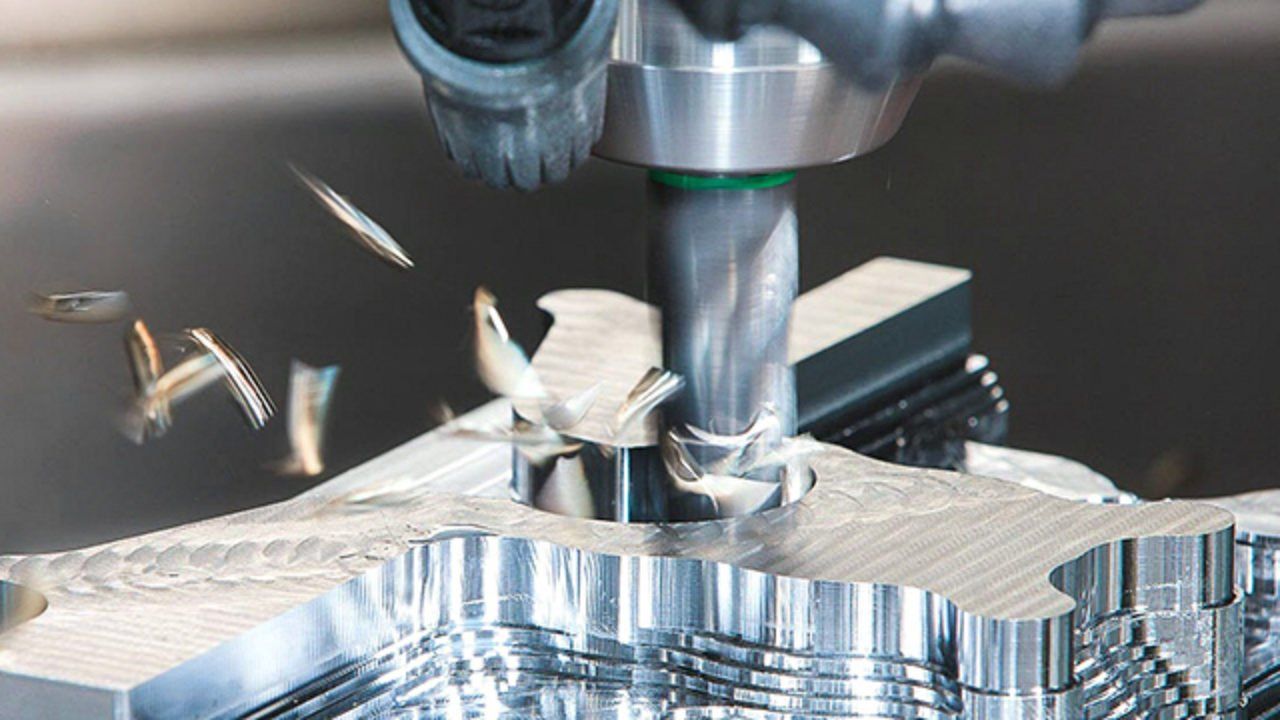

Variety of complex parts

Every single component within the aerospace industry requires precision and no room for error. When you consider the wide spectrum of required components in size, shape, and complexity, this requires a process such as CNC machining to provide this stability and consistency of performance.

Affordable process

Putting together all of the above benefits makes CNC machining an affordable long-term process for the aerospace industry. It cuts down material waste and minimises part defects that would require reworking and extra labour costs. Rapid and precise production brings down the price-per parts and increases profitability.

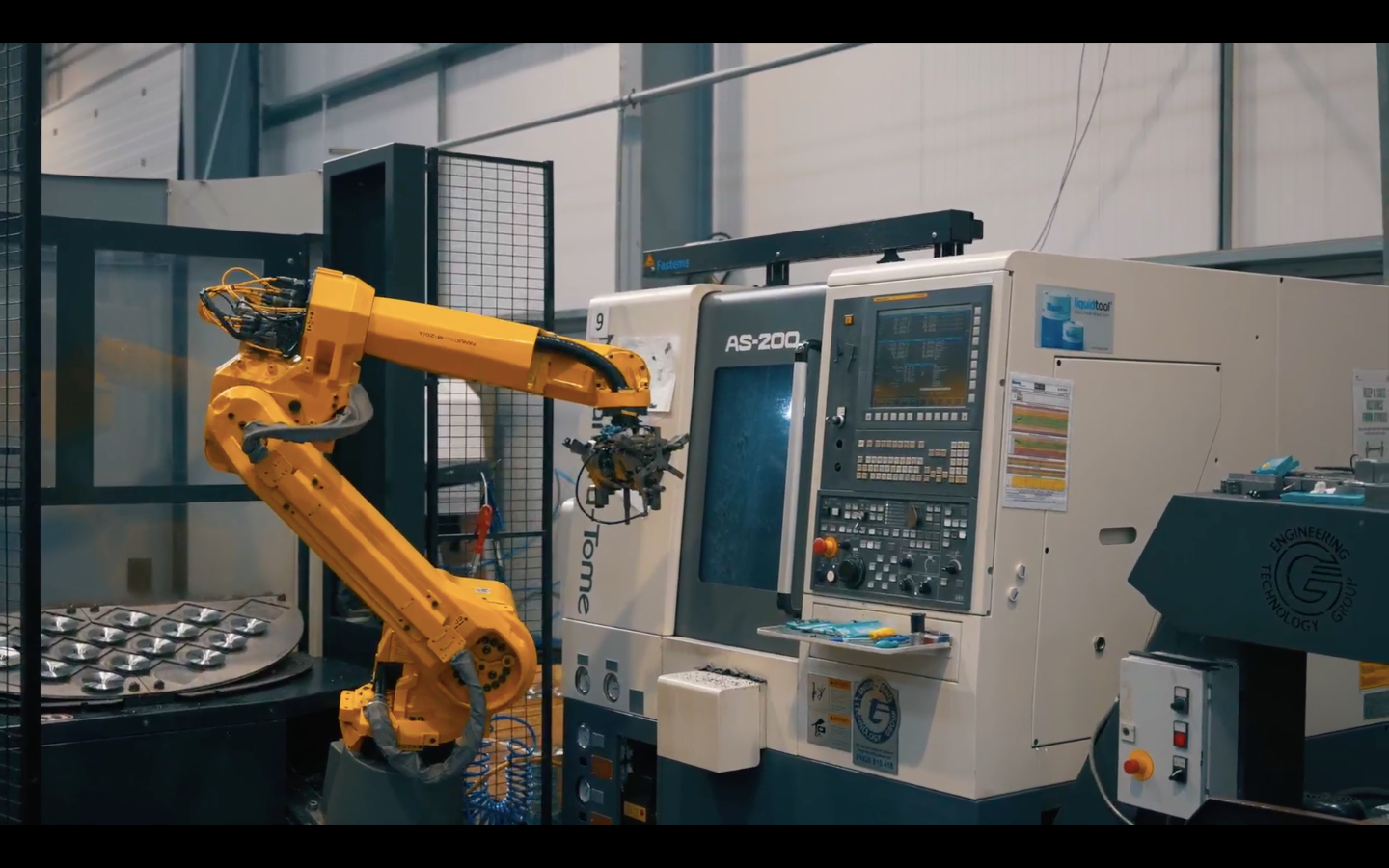

The aerospace industry relies on the production of high quality parts, utilising components that are robust and often designed with complex geometry. Rotec has the CNC machining capabilities that provide high levels of precision, automated, fast processes that create component parts that match these requirements. This accuracy is essential to produce parts for single applications or for larger production runs. Contact our team today.