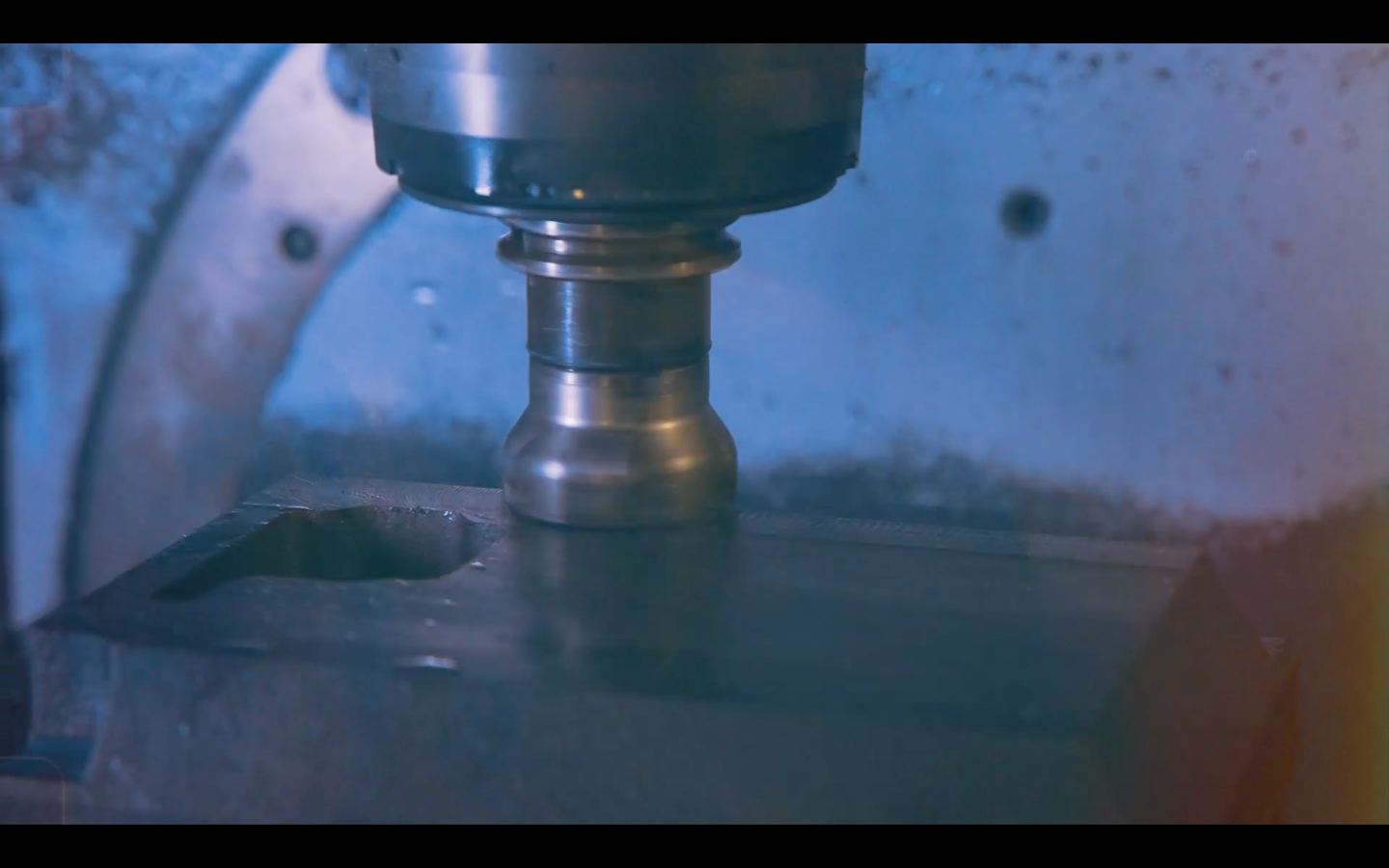

~ A Comprehensive Guide to CNC Turning Tools ~

The choice of CNC turning tools significantly influences the quality and cost of manufacturing across various industries.

CNC turning tools are an essential part of modern production machining, responsible for driving efficiency and precision in manufacturing processes. Whether you intend to do small batch runs or high-volume production, the choice of turning tools, their setup, and how they are applied can make all the difference between a smooth operation and costly setbacks.

If you are a manufacturing or engineering professional who wants to learn the basics of CNC turning tools, you have come to the right page! In this article, we will have a look at the various types of CNC turning tools, factors influencing their selection for specific cases, and key considerations for achieving optimal performance in production environments. But before we dive in, let's better understand the basic functionality of CNC turning tools.

Basic Functionality of CNC Turning Tools

CNC turning tools are designed to perform a range of operations essential for shaping and finishing workpieces. Their key functionalities include:

1. Workpiece Rotation

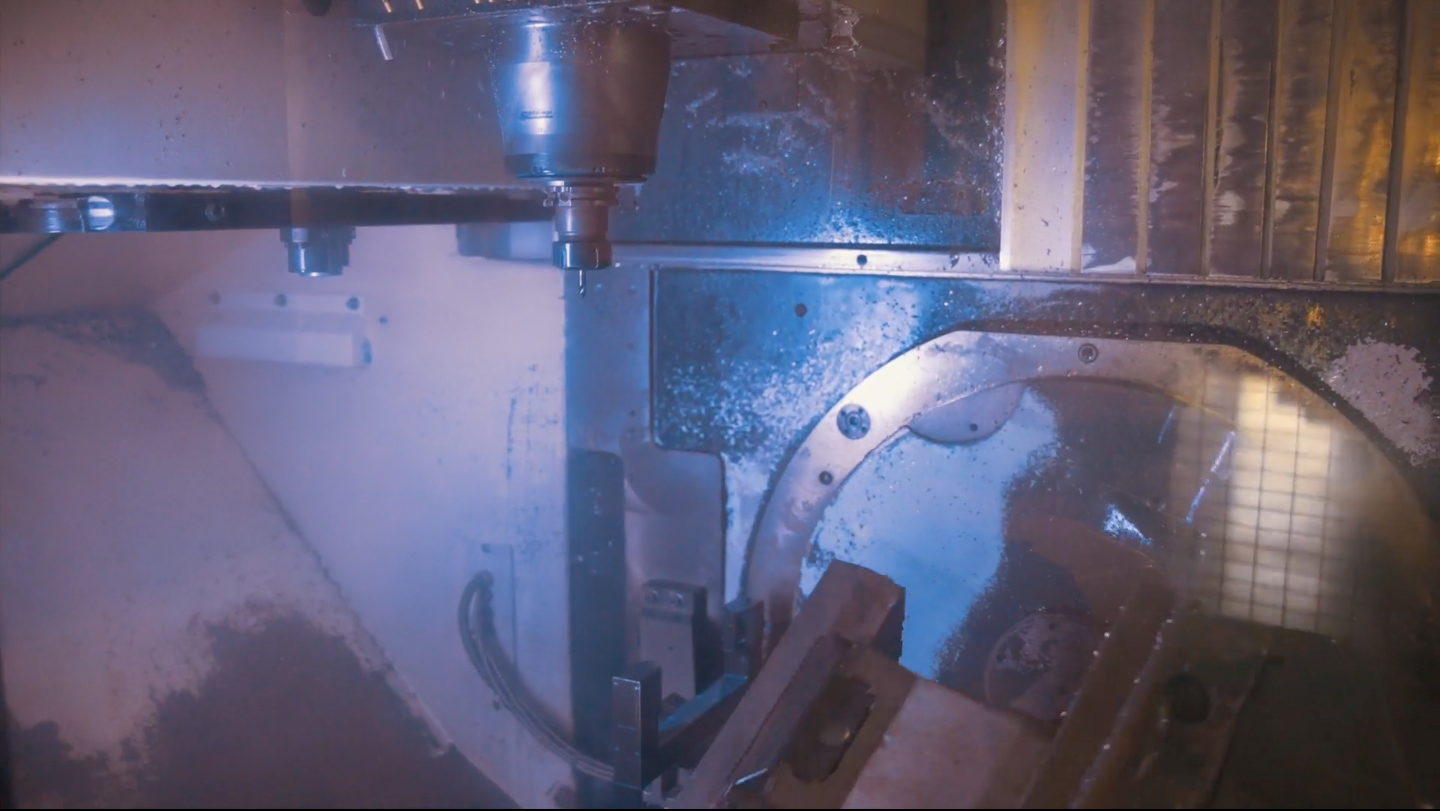

The workpiece is clamped into a rotating chuck, which spins at high speed. This rotation is essential for shaping the material.

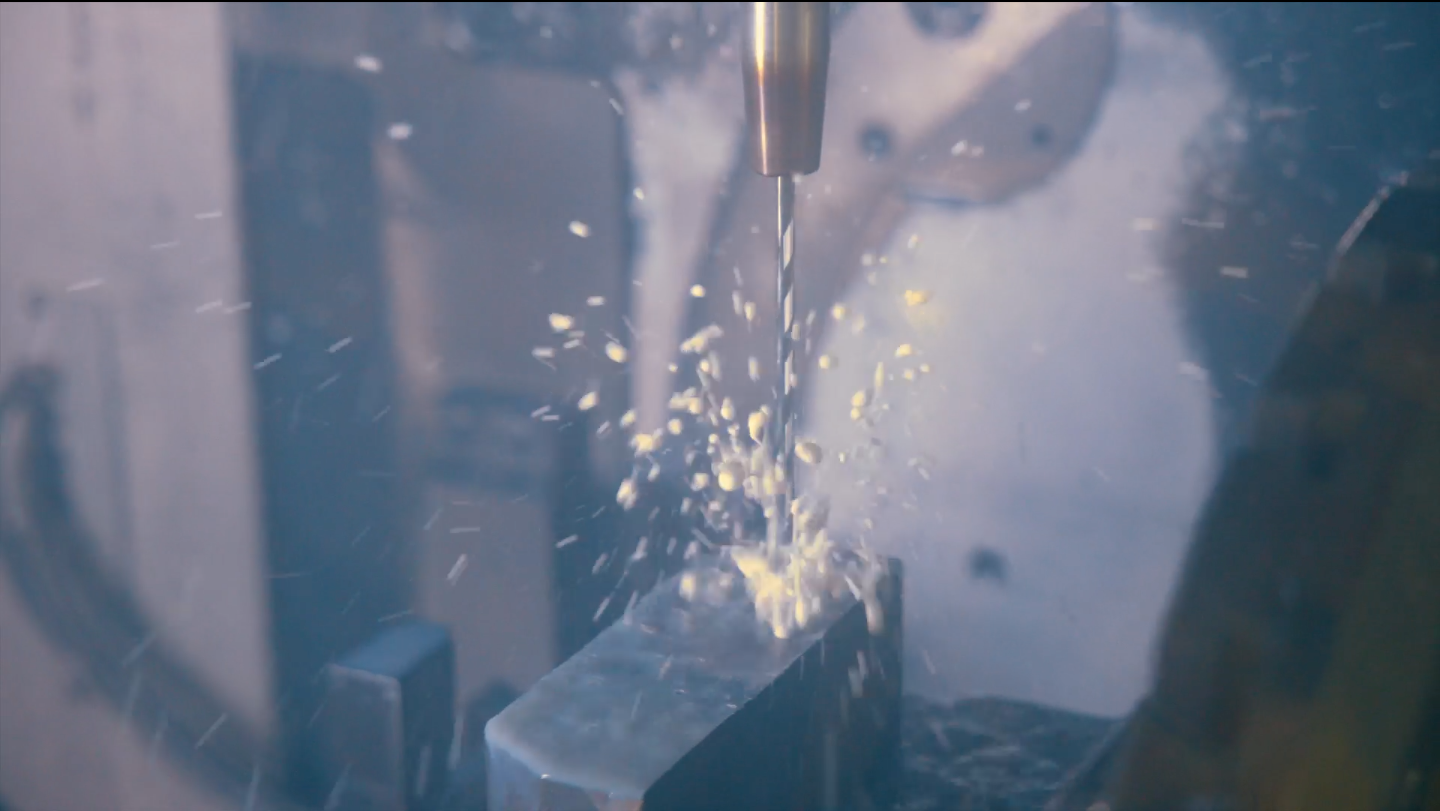

2. Cutting Tool Engagement

A stationary cutting tool made from durable materials engages the rotating workpiece, chipping away the excess material.

3. Material Removal Process

The tool cuts into the workpiece, reducing its diameter and shaping it as it follows the programmed path.

4. Control and Precision

The CNC system controls all aspects of the process, ensuring precise movement of the tool and consistent quality.

5. Tool Paths

The tool can move along different paths, such as longitudinally or perpendicularly, to create various shapes on the workpiece.

6. Finishing vs. Roughing

The tool performs roughing to remove large amounts of material and finishing for fine, precise cuts.

7. Real-Time Adjustments

The CNC system makes real-time adjustments to maintain accuracy and compensate for variables like tool wear.

Types of Turning Tools

CNC turning employs various tools tailored to specific machining operations. Some of the most commonly used turning tools include:

- Roughing Tools: Designed for removing large volumes of material quickly, roughing tools have high strength and durability. They typically feature large cutting edges and are suitable for deeper cuts and higher feed rates.

- Finishing Tools: Used for final passes, finishing tools are designed to achieve a smooth surface finish and precise dimensional accuracy. These tools have sharper edges and are intended for light cuts.

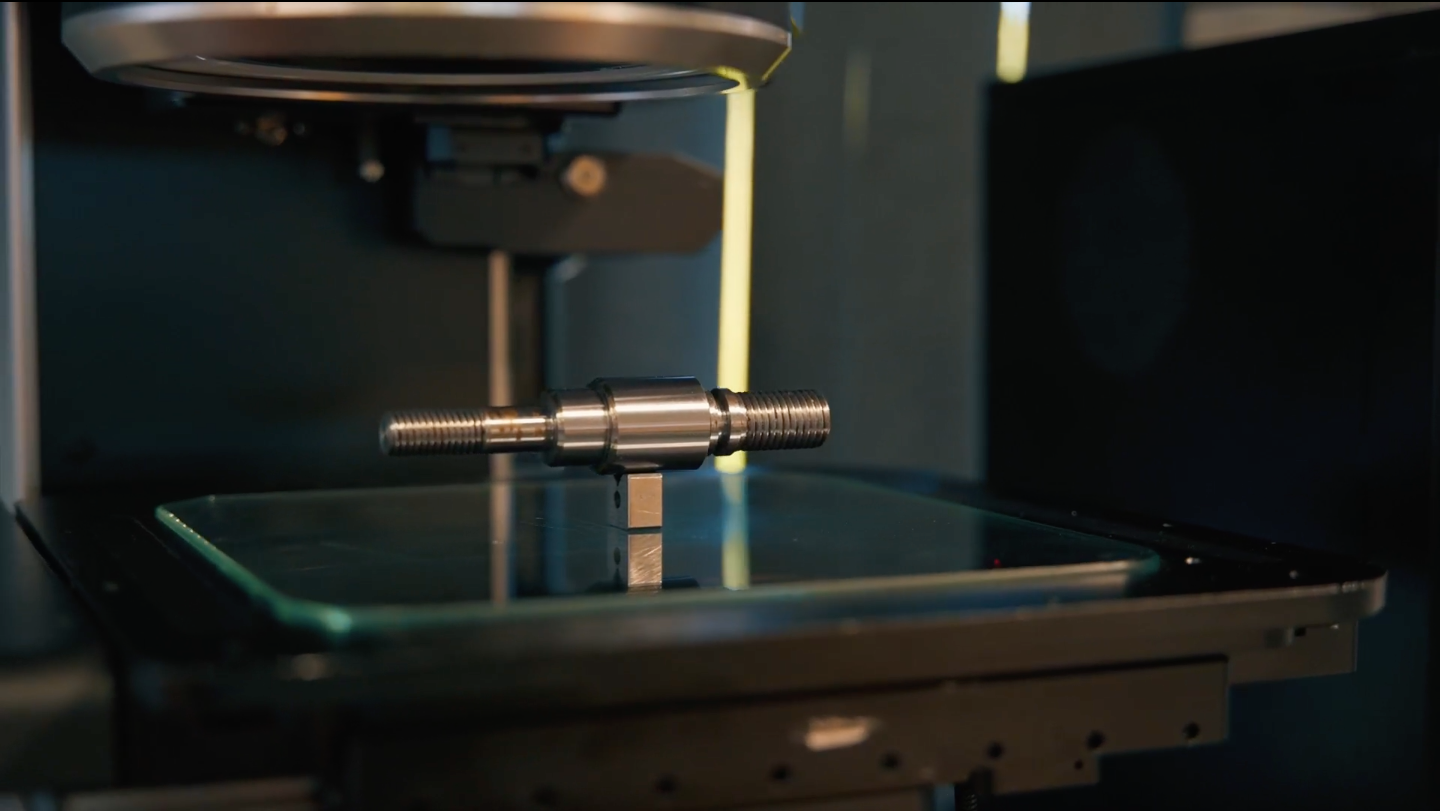

- Threading Tools: Threading tools are specialised for cutting screw threads. They come in different profiles to match thread standards (e.g., ISO metric or unified threads) and can produce both internal and external threads.

- Grooving Tools: These tools create grooves or recesses in a workpiece. Grooving tools can also be used for parting-off operations in which the finished part is separated from the rest of the material.

- Parting-Off Tools: These are designed to cut off parts from the main workpiece, typically during the final stage of the turning operation. Parting-off tools are thin to minimise material waste.

Factors that Affect the Performance of CNC Turning Tools

Material Considerations

The material of a CNC turning tool affects its performance. Common materials include:

- High-Speed Steel (HSS): Tough and suitable for general-purpose turning. Less brittle than carbide, ideal for interrupted cuts and lower speeds.

- Carbide: Known for hardness and wear resistance, carbide tools are used for high-speed cutting and offer long tool life.

- Ceramics and Cermets: Ceramics excel in heat resistance, ideal for high-speed finishing. Cermets combine ceramic and metal properties for wear resistance and toughness.

- Coated Tools: Coatings like titanium nitride (TiN) and aluminium oxide (Al2O3) enhance performance by reducing friction and extending tool life.

Tool Geometry

Tool geometry impacts cutting efficiency. Key aspects include:

- Rake Angle: Affects cutting ease and chip flow. Positive rake reduces forces but can weaken the tool, while negative rake offers stability but needs more power.

- Clearance Angle: Ensures only the cutting edge engages the workpiece, reducing friction and preventing rubbing.

- Nose Radius: Influences surface finish and strength. A larger radius improves finish but requires more stable conditions.

Selection Criteria for CNC Turning Tools

Choosing the right turning tool involves balancing multiple factors to achieve optimal results in terms of speed, accuracy, and cost. Key considerations include:

Material Being Machined

Softer materials like aluminium may require tools with sharp edges and minimal coating, while harder materials such as stainless steel or titanium benefit from tougher tools with specialised coatings.

Cutting Speed, Depth of Cut, and Feed Rate

These three parameters are interdependent and must be adjusted to match the selected tool:

- Cutting Speed: Higher speeds often improve productivity but may lead to faster tool wear. Carbide tools can handle higher speeds than HSS or ceramics, but the optimal speed depends on the workpiece material and tool geometry.

- Depth of Cut: The depth of cut affects the amount of material removed per pass. Roughing operations usually require deeper cuts, necessitating tools with robust edges, while finishing operations use lighter cuts.

- Feed Rate: The feed rate is the speed at which the tool advances along the workpiece. Higher feed rates can increase material removal rates but may compromise surface finish and put more strain on the tool.

Tolerance Requirements and Surface Finish

The tighter the tolerance and smoother the required surface finish, the more specific the tool selection becomes. Finishing tools with sharp edges and small nose radii are typically chosen for such operations to achieve high-quality results.

Balancing Tool Life and Cutting Performance

Longer tool life reduces downtime and the need for frequent tool changes. To extend tool life, manufacturers consider tool coatings, cooling strategies, and appropriate speeds and feeds. However, prioritising tool life over cutting speed may reduce output, so a balance must be found based on production goals.

Tool Rigidity and Stability

Tool rigidity is vital for both precision and surface quality. Any tool deflection can result in poor finishes, dimensional inaccuracies, and increased wear. Tool holders and machine settings must be selected to provide adequate support and minimise vibration.

Advanced Turning Techniques

CNC turning continues to evolve with methods that improve efficiency and precision.

High-Speed and High-Feed Turning

High-Speed Turning: Involves higher cutting speeds with moderate feeds, suitable for ceramics or carbide tools, enabling faster machining.

High-Feed Turning: Prioritises higher feed rates with shallow cuts for quick material removal. Specialised inserts handle the higher load.

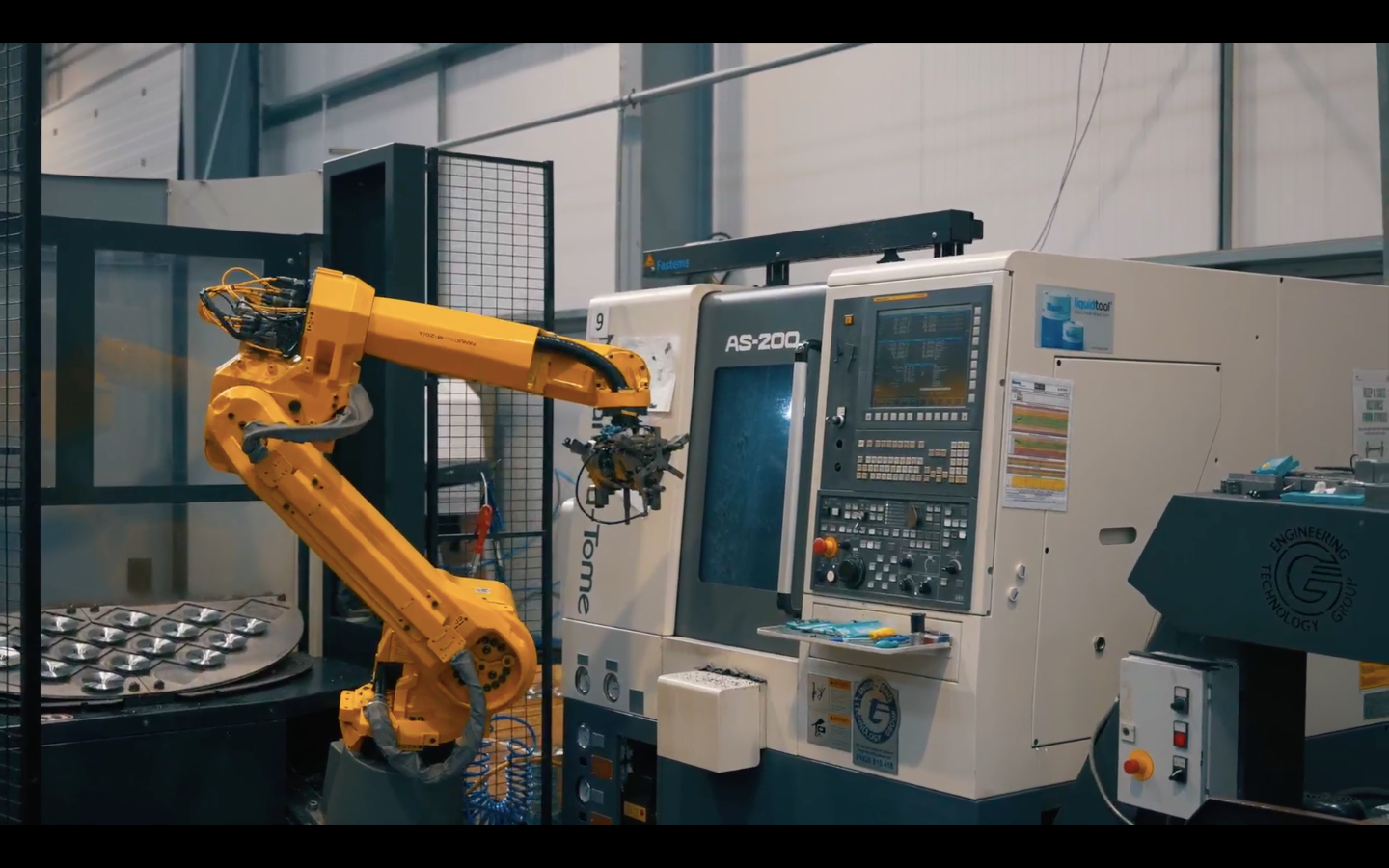

Multi-Tasking Operations

Machines with live tooling can perform multiple tasks — like turning, milling, and drilling — in one setup, improving productivity. Live tooling adds flexibility for operations such as slotting and drilling without switching setups.

Adaptive Tool Paths

Adaptive machining uses dynamic tool paths that reduce wear while maintaining consistent removal rates. Techniques like trochoidal turning reduce cutting forces, optimising performance in tough materials.

Maintenance of CNC Turning Tools

Understanding tool wear and implementing proper maintenance ensures consistent performance and cost control.

Monitoring Tool Condition

Regular inspections and in-process monitoring through sensors for quality analysis help maintain tool integrity and avoid unexpected failures.

Extending Tool Life

Best practices for extending tool life include: using coated tools, optimising cutting parameters, applying proper coolant, and reconditioning tools to extend their lifespan.

Why It’s Best to Leave CNC Turning Tool Operation to the Experts

Letting experts handle

CNC turning tool operations is essential for several key reasons:

1. Precision and Quality

CNC turning requires meticulous control over tool selection, setup, and machining parameters. Experts ensure that parts meet tight tolerances and achieve the desired surface finish, avoiding costly defects or rework.

2. Optimal Tool Selection and Setup

Professionals know how to match the right tools and inserts to specific materials and tasks. They can set up the machine accurately, ensuring proper alignment and tool positioning, which is crucial for efficient and precise machining.

3. Problem Solving

Experienced machinists can quickly diagnose and fix issues like tool wear, vibration, or poor chip formation. They adjust parameters or change tools as needed to maintain consistent output and prevent costly downtime.

4. Maximising Tool Life

Tool wear management is critical to reducing costs. Experts implement effective strategies, such as optimising coolant use and adjusting speeds, to extend tool life, reduce breakage, and maintain smooth production.

5. Safety and Compliance

CNC turning involves risks like high speeds and rotating parts. Trained professionals follow safety protocols, ensuring proper tool handling and machine operation while adhering to industry standards.

6. Advanced Techniques

Experts stay updated on the latest technologies and techniques, from high-speed turning to live tooling. This knowledge improves efficiency, quality, and the ability to handle complex machining tasks.

7. Cost Efficiency

While DIY machining may seem cheaper, errors, poor tooling choices, and inefficiencies often lead to higher overall costs. Professionals ensure smooth, productive operations, saving time and resources.

Case Studies and Industry Applications

The choice of CNC turning tools significantly influences the quality and cost of manufacturing across various industries. Whether in aerospace or medical manufacturing, using the right tools and strategies ensures precise and reliable production of complex components.

Aerospace Industry

In aerospace manufacturing, CNC turning is commonly used to produce components such as turbine blades, shafts, and engine casings. The industry frequently works with high-strength materials like titanium alloys, Inconel, and stainless steel, which present significant machining challenges due to their hardness and heat resistance.

Case Study: A leading aerospace manufacturer improved productivity and tool life by adopting ceramic inserts for high-speed turning of Inconel parts. Ceramic tools, combined with optimised cooling and adaptive tool paths, allowed for faster machining without compromising precision. The switch resulted in a 30% reduction in cycle time and a marked improvement in surface finish.

Tooling Considerations: The use of high-performance tools, such as CBN or ceramic inserts, is essential in aerospace due to the extreme conditions in which parts operate. Balancing tool wear with precision machining ensures that components meet strict safety and performance standards.

Automotive Industry

The automotive sector requires the mass production of high-precision parts, such as engine components, shafts, and gears. CNC turning is a key process in this industry, where both speed and accuracy are paramount.

Case Study: An automotive supplier faced high tool wear when machining hardened steel shafts. By transitioning to coated carbide inserts with optimised cutting geometries, the company significantly reduced tool changeover frequency. The introduction of automated tool change systems further improved efficiency, allowing for continuous production with minimal downtime. The result was a 20% increase in throughput and a notable reduction in tooling costs.

Tooling Considerations: High-feed turning and automated systems are essential in automotive production, where the focus is on consistency, repeatability, and reducing cycle times. Tool coatings play a critical role in maintaining performance under high-speed, high-load conditions.

Medical Industry

In the medical field, components such as implants, surgical instruments, and prosthetics require minute detailing and tight tolerances. Materials like stainless steel, cobalt-chromium alloys, and titanium are frequently used, necessitating specialised tooling solutions.

Case Study: A manufacturer of medical implants needed to produce high-precision titanium parts with mirror-like surface finishes. By implementing diamond-coated tools and adjusting machining parameters for ultra-fine finishing, the company achieved the desired results. In addition, multi-tasking lathes with live tooling enabled the completion of complex geometries in a single setup, reducing lead times.

Tooling Considerations: The medical sector places emphasis on both dimensional accuracy and biocompatibility, requiring tools that can achieve tight tolerances without contaminating the workpiece. Hybrid tools and advanced coatings are often deployed to meet these requirements.

Final Thoughts

Understanding the specific requirements of the project at hand and having a clear understanding of CNC machining lets you make informed choices that improve the final outcomes while reducing costs. With that being said, it's best to work closely with a precision engineering company to achieve the best results in your project.

If your company is looking for cutting-edge solutions in CNC turning and complex machining, look no further than Rotec. Our team of engineers with decades of combined experience in advanced CNC turning technologies, combined with our commitment to quality and innovation, ensures that we deliver solutions tailored to your specific needs.

Contact us to discuss your requirements today!