~ The Evolution and Applications of CNC Technology ~

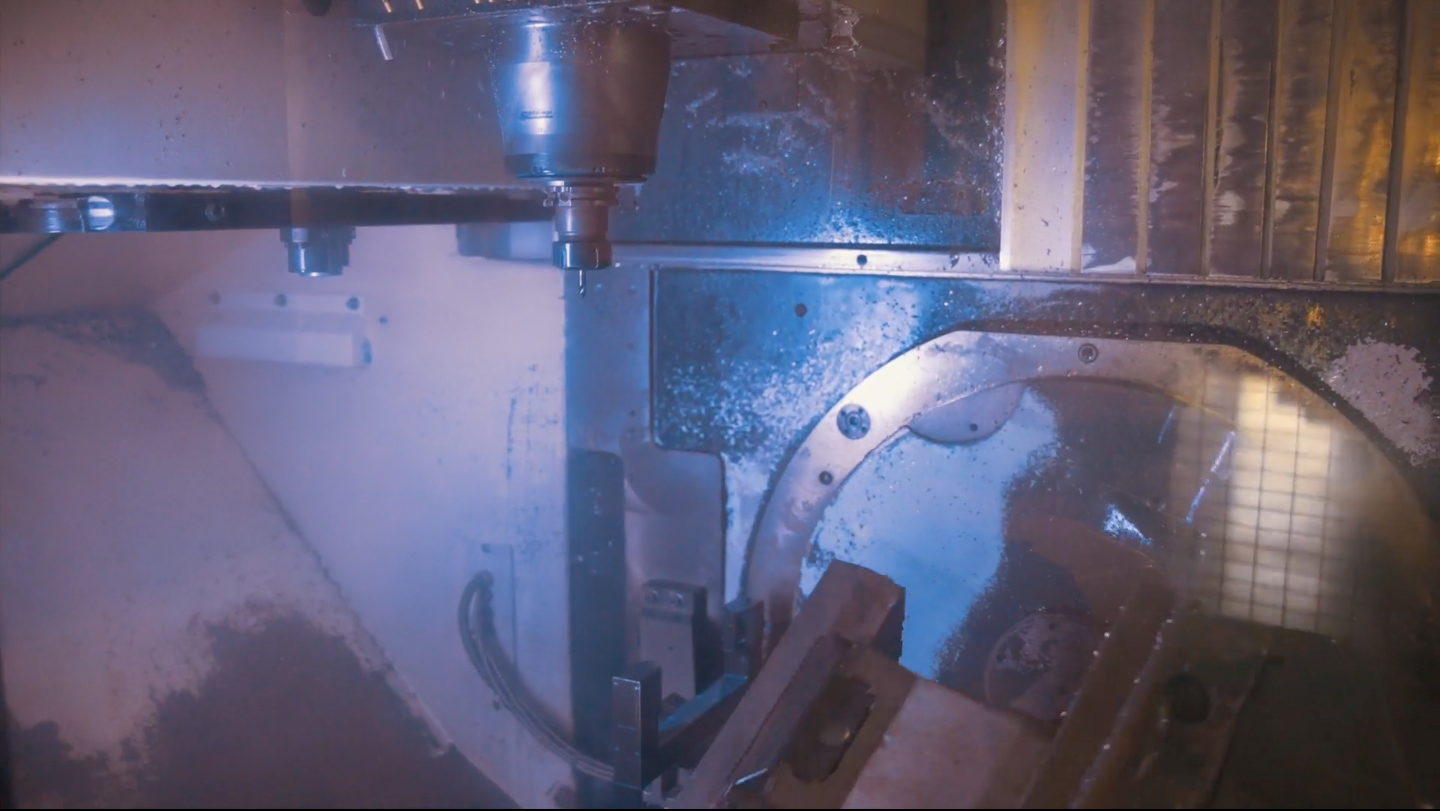

Computer Numerical Control (CNC) machining has revolutionised the manufacturing landscape, becoming a cornerstone of modern industry.

CNC machining involves the use of computerised systems to control and manipulate tools for precision machining of various materials. The impact of CNC technology is profound, enabling unparalleled levels of accuracy, efficiency, and customisation in manufacturing processes. To fully appreciate its significance, we need to look at the pivotal moments and technological breakthroughs that have shaped the foundation for CNC technology, exploring the milestones, challenges, and innovations that have defined this transformative field.

If you want to learn more about how CNC machining has evolved over the decades to get to where it is now, you have come to the right page! In this article, we will delve into the fascinating history of CNC machining, tracing its evolution from rudimentary numerical control systems to the sophisticated and interconnected CNC systems of today. Not only that, we will also have a look at the ongoing technological advancements and what the future holds for this groundbreaking technology. Without further ado, let's dive right in!

Evolution of CNC Technology Over Decades

1950s - Early Concepts and Precursors

Development of Numerical Control (NC) Systems: In the 1950s, the groundwork for CNC machining was laid with the development of numerical control systems. Engineers and researchers explored ways to automate machining processes, setting the stage for the technological leaps that would follow.

Application in Military and Aerospace Industries: The military and aerospace sectors played a crucial role in the early adoption of numerical control. CNC technology emerged as a solution to enhance precision and efficiency in manufacturing components for complex aircraft and defence systems.

1960s - First Steps Towards Automation

Punched Tape Systems: The 1960s witnessed the introduction of punched tape systems, a primitive form of programming for machining operations. While limited, these early automation methods represented a fundamental shift towards more efficient and accurate machining processes.

Limited Programmability, Challenges and Solutions: Despite advancements, the programmability of early CNC systems was constrained. Engineers faced challenges in programming complex shapes and patterns. However, these limitations spurred further innovation, paving the way for more sophisticated programming languages.

1970s - Birth of CNC Machining

Introduction of Computers to Machining: The 1970s marked a pivotal moment with the introduction of computers to machining processes. This era saw a transition from analog to digital control, allowing for greater flexibility and precision in machining operations.

Emergence of the Term CNC (Computer Numerical Control): As computers became integral to machining, the term "Computer Numerical Control" (CNC) was coined to describe this revolutionary approach. CNC represented a paradigm shift in manufacturing, bringing about a new era of automated and computer-driven machining.

Development of the First CNC Machine Tool: Visionaries like John T. Parsons and the MIT Servomechanisms Laboratory developed the first CNC machine tool during this period. This groundbreaking innovation laid the foundation for the widespread adoption of CNC technology across various industries.

1980s - Transition from Punched Tapes to Computer Programming

Elimination of Punched Tape Limitations: The 1980s witnessed the gradual phasing out of punched tape systems. This transition allowed for more sophisticated programming methods, eliminating the constraints imposed by punched tape technology.

Integration of Computers in CNC Machining: The integration of computers in CNC machining became more seamless, leading to improved accuracy and versatility in manufacturing processes. CNC machines evolved to handle complex tasks with greater efficiency.

Early Programming Languages and Advances: During this period, early programming languages for CNC machining, such as G-code, gained prominence. These languages enabled operators to communicate complex instructions to CNC machines, expanding the scope of achievable shapes and designs.

1990s - Advancements in Control Systems

Open-Loop vs. Closed-Loop Systems: The 1990s brought advancements in control systems, distinguishing between open-loop and closed-loop CNC systems. Closed-loop systems, incorporating feedback mechanisms, enhanced precision and reliability in machining operations.

Integration of Microprocessors in CNC Machines: Microprocessor technology became integral to CNC machines, allowing for faster computation and more intricate control. This era marked a significant leap in the overall performance and capabilities of CNC systems.

2000s - Expansion of CNC Applications

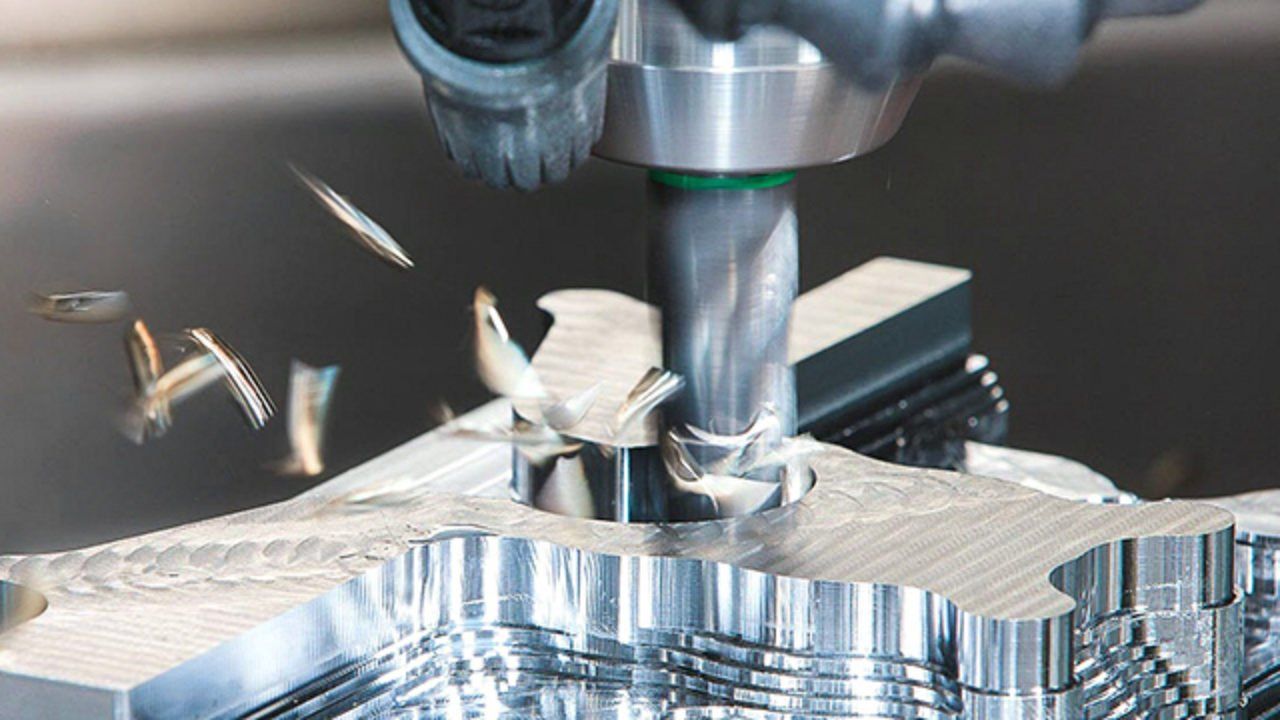

CNC Turning and Milling Machines: The 2000s witnessed a proliferation of CNC applications, with a focus on turning and milling machines. These CNC systems allowed for the precise shaping of raw materials into intricate components, facilitating mass production with unprecedented accuracy.

Multi-Axis Machining Centers: Advancements in multi-axis machining centres became a hallmark of the 2000s. These machines enabled complex and multi-dimensional machining, expanding the possibilities for intricate part production in industries ranging from automotive to aerospace.

Introduction of Waterjet and Laser Cutting Systems: CNC technology embraced new frontiers with the introduction of waterjet and laser cutting systems. These technologies allowed for non-traditional machining methods, offering precision in cutting a variety of materials, from metals to composites.

2010s - Software Developments

CAD/CAM Integration for Enhanced Design and Manufacturing: The 2010s marked a significant emphasis on Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) integration. This synergy between design and manufacturing software streamlined processes, enabling seamless transitions from digital models to physical prototypes.

Simulation and Verification Tools for Precision: The advent of simulation and verification tools in CNC machining during this decade enhanced precision and minimised errors. Engineers could simulate machining processes virtually, allowing for the identification and correction of potential issues before the physical machining began.

Ongoing Technological Advancements in CNC

High-Speed Machining Techniques: The 2020s saw a continued focus on high-speed machining techniques. Enhanced spindle speeds and cutting strategies allowed for faster production while maintaining precision, catering to the demands of modern manufacturing.

Internet of Things (IoT) Integration in CNC Machines: IoT integration became increasingly prevalent in CNC machines. Connected CNC systems facilitated real-time monitoring, predictive maintenance, and data-driven optimisation, contributing to overall efficiency and machine health.

Augmented Reality (AR) and Virtual Reality (VR) Applications in CNC: The integration of Augmented Reality (AR) and Virtual Reality (VR) applications in CNC machining provided innovative solutions for training, simulation, and maintenance. These technologies enhanced the user experience, making CNC operations more intuitive and accessible.

Future Trends and Anticipated Developments

Additive Manufacturing and CNC Integration: The synergy between additive manufacturing (3D printing) and CNC machining is anticipated to grow, offering a hybrid approach that combines the benefits of both technologies.

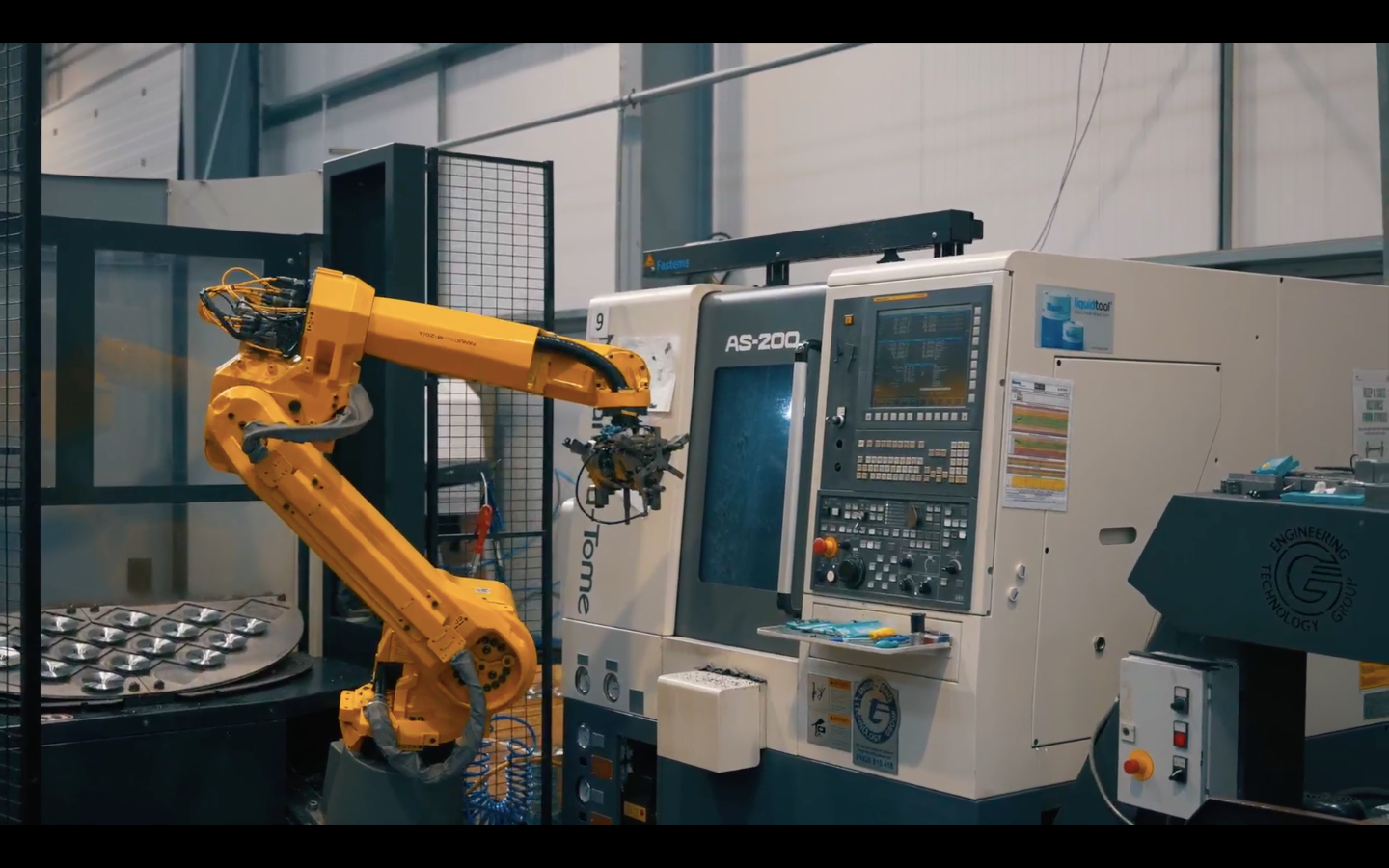

Robotics and Automation in CNC Processes: The integration of robotics and automation into CNC processes is expected to increase, further reducing manual intervention, improving efficiency, and enabling lights-out manufacturing.

Sustainable and Green CNC Practices: Future trends in CNC machining are likely to include a focus on sustainable and environmentally friendly practices. This may involve the adoption of greener materials, energy-efficient machining processes, and waste reduction initiatives.

Impact of CNC Machining on Manufacturing Industries

CNC machining has exerted a transformative influence on manufacturing industries, shaping the way products are conceptualised, designed, and produced. This section explores the profound impact of CNC technology on various facets of manufacturing, illustrating its role in enhancing precision, enabling mass production, and contributing to advancements in critical industries.

Increased Precision and Efficiency

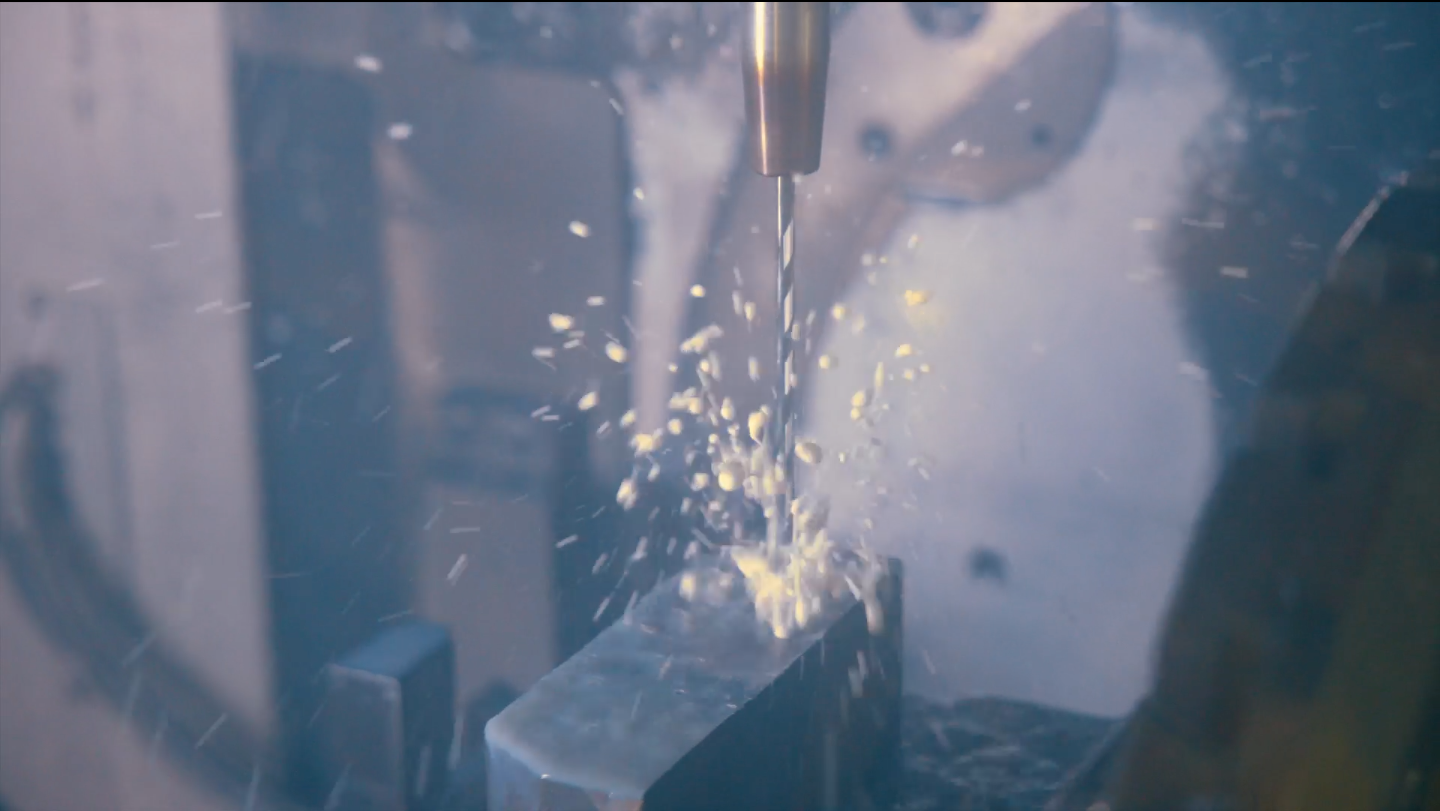

The advent of CNC machining brought a paradigm shift in precision engineering. The ability to program and automate machining processes down to micrometre-level accuracy revolutionised the production of intricate components. CNC machines consistently deliver high precision, reducing errors and ensuring conformity to exact specifications. This precision is especially critical in industries such as aerospace and medical, where tight tolerances are non-negotiable.

Beyond precision, CNC machining significantly improved efficiency. The automation of repetitive tasks eliminated the variability associated with manual operations, resulting in faster production cycles and reduced lead times. This efficiency not only enhances productivity but also contributes to cost-effectiveness in the long run.

Mass Production and Customisation

CNC machining played a pivotal role in the shift from traditional manufacturing to mass production. The ability to reproduce complex components with unparalleled accuracy allowed industries to scale production without compromising quality. This scalability is particularly evident in automotive manufacturing, where CNC technology enables the efficient production of large quantities of standardised parts.

Simultaneously, CNC machining facilitated a paradoxical trend towards customisation. While mass-producing standardised components, CNC machines can swiftly switch between designs, accommodating variations in product specifications. This flexibility has empowered industries to meet the growing demand for customised and specialised products, from personalised medical implants to uniquely designed automotive components.

Small Business and Customisation

CNC for Small and Medium-Sized Enterprises (SMEs)

The accessibility of CNC machines has levelled the playing field for small and medium-sized enterprises. SMEs can harness the power of CNC technology to compete on quality and precision, enabling them to take on projects that were once exclusive to larger corporations.

Having worked closely with small businesses, we have seen firsthand the transformative impact of CNC technology. It's not just about the machines; it's about empowering smaller players to dream big and innovate.

Customisation and Prototyping Services

CNC machining's ability to facilitate rapid prototyping has revolutionised the product development cycle. Whether it's a one-of-a-kind design or a prototype for mass production, CNC's flexibility allows for quick iterations, reducing time-to-market and fostering a culture of innovation.

In the realm of creativity and design,

acrylic CNC machining acts as a versatile tool for turning imaginative concepts into tangible prototypes. It's a game-changer for those pushing the boundaries of what's possible.

Applications Across Industries

CNC machining has found diverse applications across various industries, each benefiting from its unique capabilities.

Electronics and Semiconductors

In the electronics sector, CNC technology is crucial for the precision machining of intricate components on circuit boards. The miniaturisation trend in electronics demands microscopic precision, a feat efficiently achieved by CNC machines. Moreover, CNC machining plays a pivotal role in the production of semiconductor components, contributing to the rapid advancements in technology.

Consumer Goods Manufacturing

CNC machining has permeated the consumer goods manufacturing sector, allowing for the efficient production of products ranging from kitchen appliances to consumer electronics. The ability to seamlessly transition from prototyping to mass production caters to the dynamic nature of consumer preferences and market trends.

Aerospace Industry

CNC machining is indispensable in aerospace manufacturing for its ability to craft precision components crucial for aircraft and spacecraft. From turbine blades to structural components, the aerospace sector relies on CNC technology to meet the stringent demands of high-performance and safety standards.

Automotive Industry

In the automotive sector, CNC machining has become synonymous with efficiency and precision. From engine parts to intricate components in modern vehicles, CNC technology plays a central role in ensuring the reliability and performance of automobiles. Moreover, CNC machines are vital in prototyping and developing new automotive designs.

Medical Industry

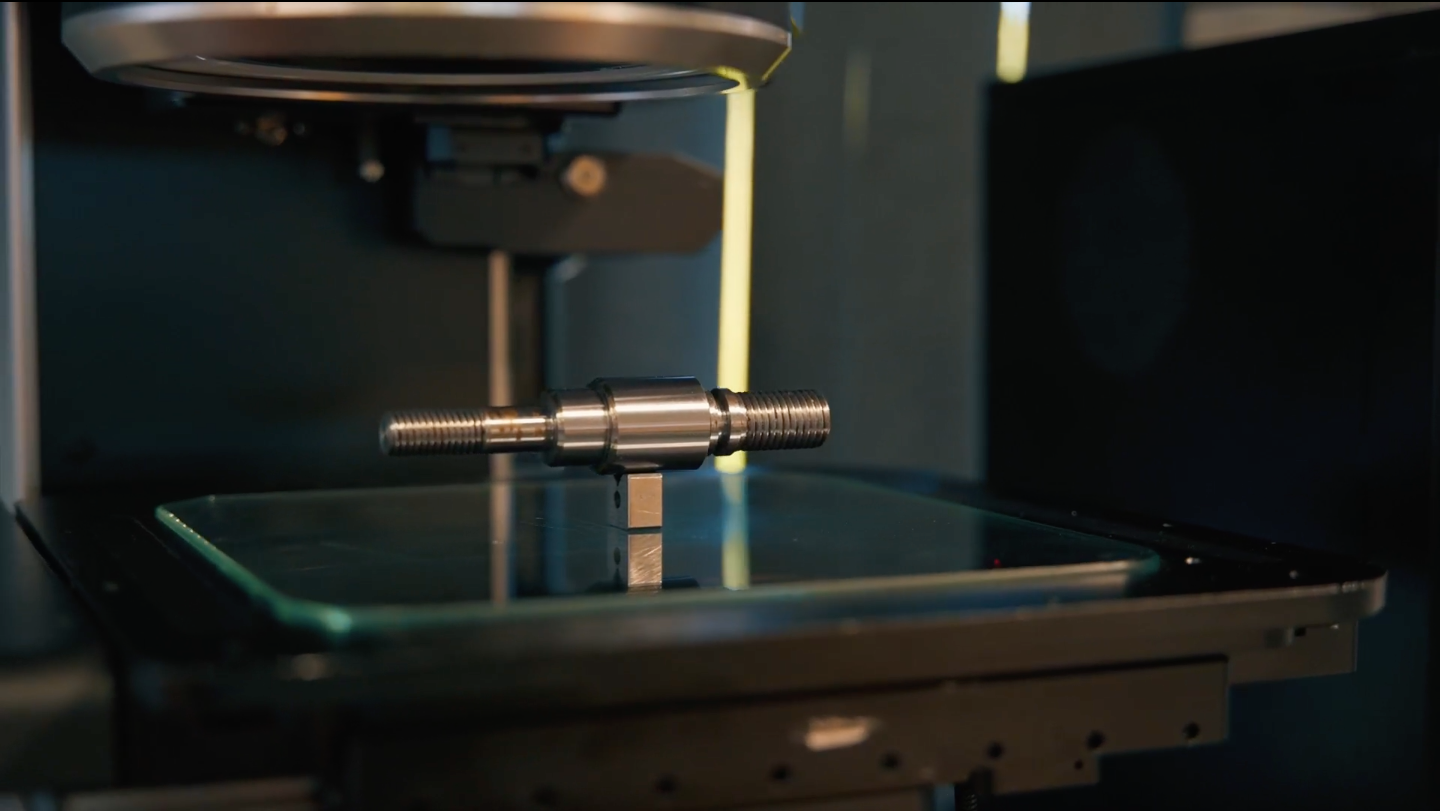

In the medical field, CNC machining is instrumental in the production of medical devices, implants, and prosthetics. The ability to create complex and customised components with biocompatible materials has revolutionised medical manufacturing, offering patients tailored solutions and improving the overall quality of healthcare.

As CNC machining continues to evolve, its impact on manufacturing will only deepen. The increased precision, scalability, and flexibility provided by CNC technology have positioned it as a cornerstone of modern industrial processes.

Final Thoughts

From its humble beginnings to its current state as an integral part of industries worldwide, the story of CNC machining evolution is one of ingenuity, adaptability, and the relentless pursuit of manufacturing excellence. Looking ahead, the anticipated trends of additive manufacturing integration, robotics, and sustainable practices signify a future where CNC machining will continue to be a driving force in shaping the manufacturing landscape.

At Rotec, we specialise in turning possibilities into reality, crafting intricate components that redefine industry standards.

Contact us today to explore how our cutting-edge CNC and precision engineering capabilities can support your ongoing or upcoming projects!